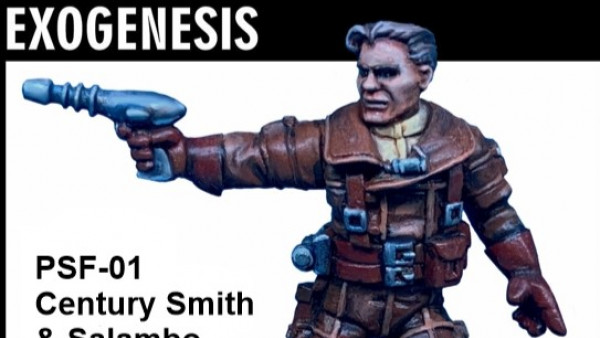

Edo Strider for Counterblast™

Moulding & Casting

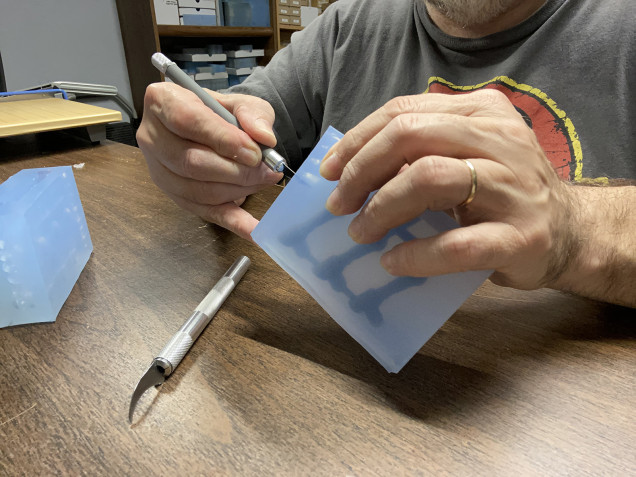

Once the silicone cures, the moulds are unboxed and cut to remove the master prints. The incisions to split the mould open are cut in a zig-zag pattern back and forth to crreate “keys” that will allow the mould to fit back together in place. Without these keys the mold may not align properly and the castings would have a distinct step along where the part line runs around the piece.

Once all of the master prints are extracted a test run is cast to see how the parts come out. This is where I check to see how to fill the mould, where the resin flows properly and if the air escapes from the pockets where it should. Then if any adjustments need to made on subsequent runs, I can make those during the casting pours.

Next up we will clean the parts and do a test assembly before painting.

![How To Paint Moonstone’s Nanny | Goblin King Games [7 Days Early Access]](https://images.beastsofwar.com/2024/12/3CU-Gobin-King-Games-Moonstone-Shades-Nanny-coverimage-225-127.jpg)

Leave a Reply