3D Wolsung Terrain (spring cleaning challenge 2023)

Recommendations: 452

About the Project

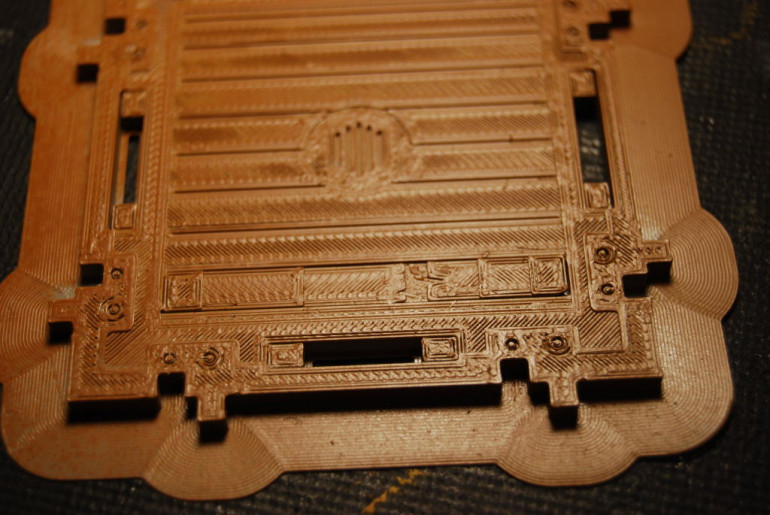

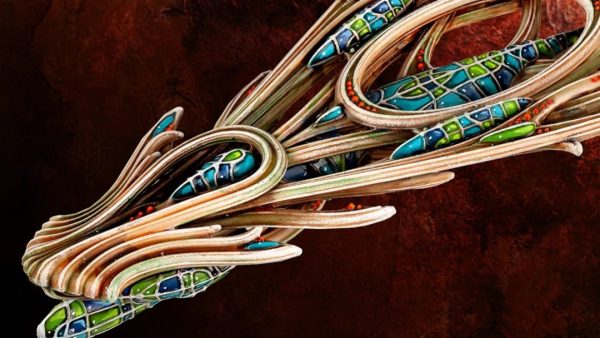

Back around 2017, after watching BOW-OTT demoing Wolsung steampunk skirmish game i was hooked. I back their first Kick starter and started playing some game with what hero and henchmen i could get on Ebay. I always love the Wolsung terrain but it was hard to find here in the US. 2017 I also got my first 3D printer and try to create some terrain to match the MDF terrain from Micro arts studio was a disaster for the start. The PLA filament i used cause a lot of issue with the 3D model i made in tinker CAD. Clogging and under extrusion made my first prints weak and unusable. My plans to make the interior of an Airship were dashed :(. Fast forward to today i have desided give this project another go and see what i can do.

Related Game: Wolsung SSG

Related Genre: Steampunk

Related Contest: Spring Clean Hobby Challenge 2023

This Project is Active

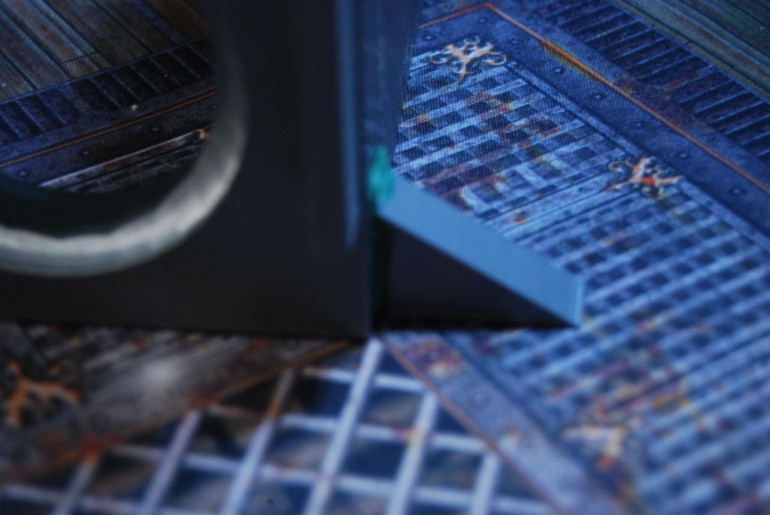

adding some small details

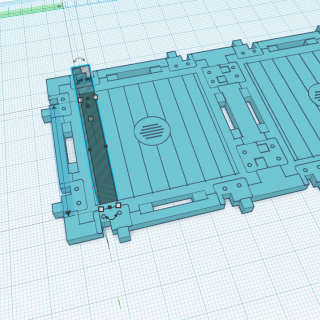

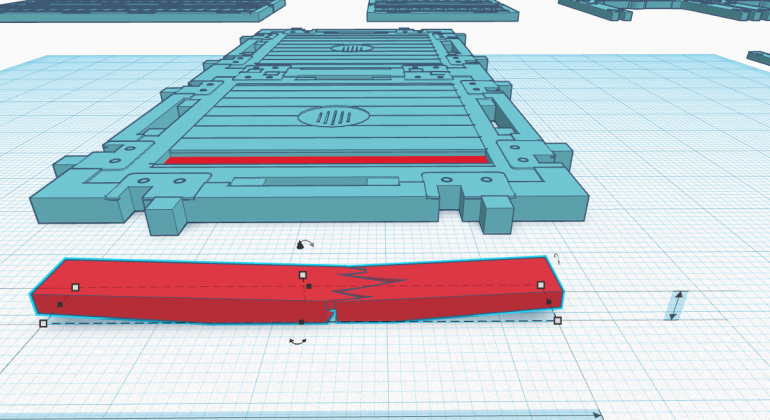

If you ever walked on an old wooden boardwalk, You would encounter a few broken boards along the way. I wanted to add that to Wolsung :).

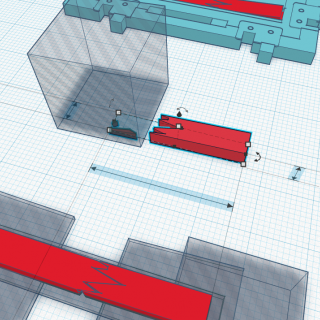

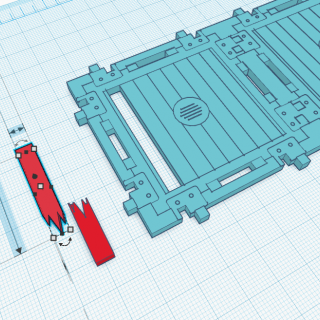

First i had to remove a board section. then i created a rectangle to match the board shape. i use a negative image of a star pattern to create the broken edges. Clean up both sides and fitted them back in the walkway.

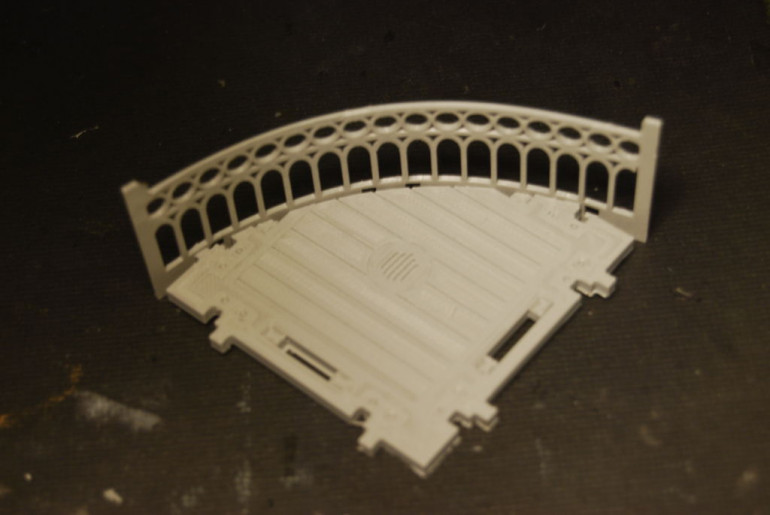

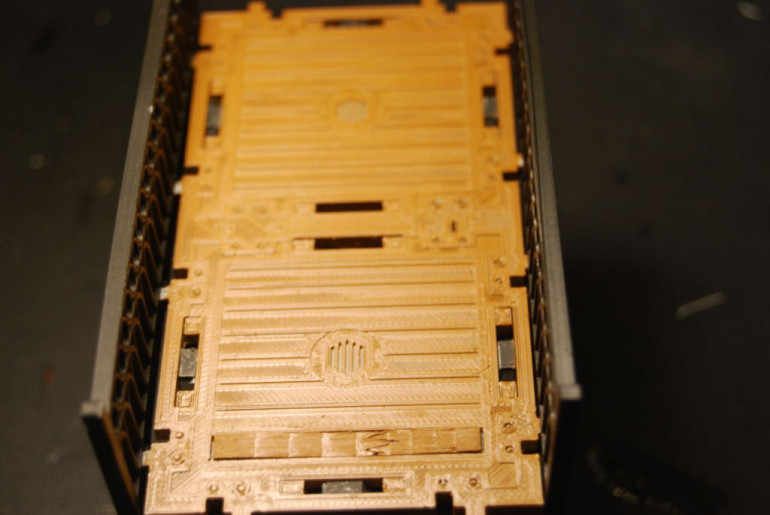

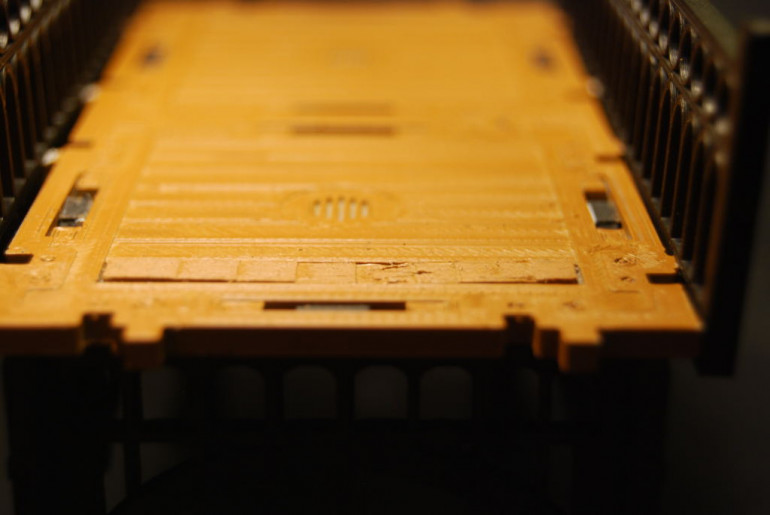

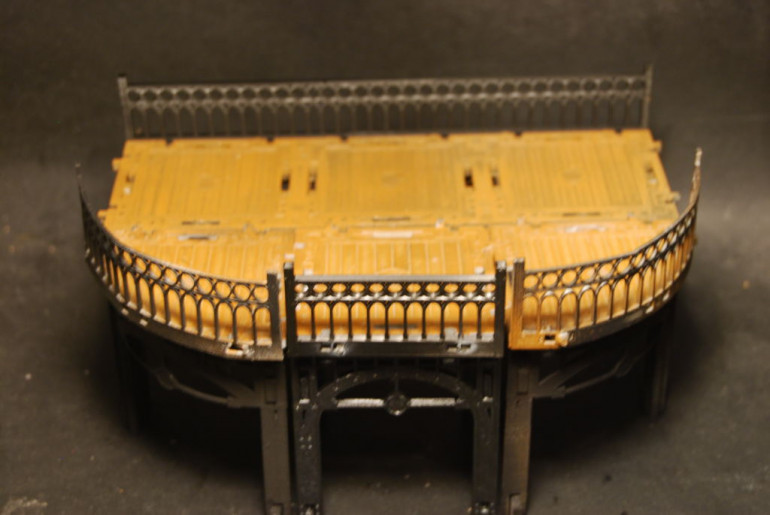

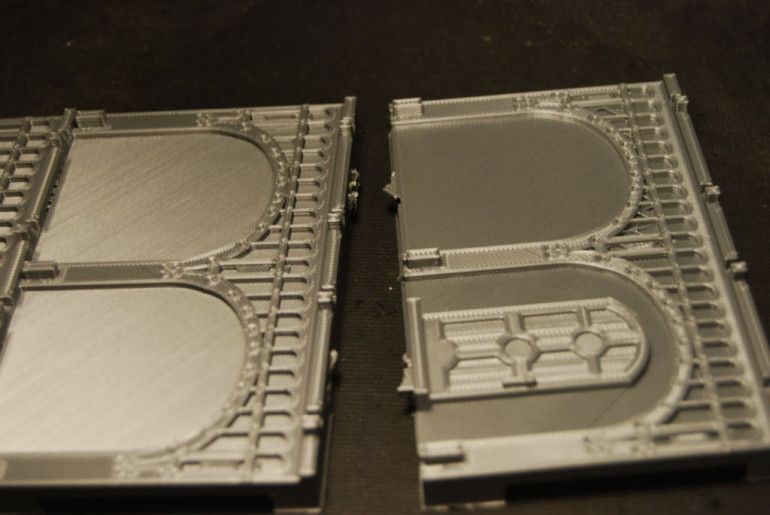

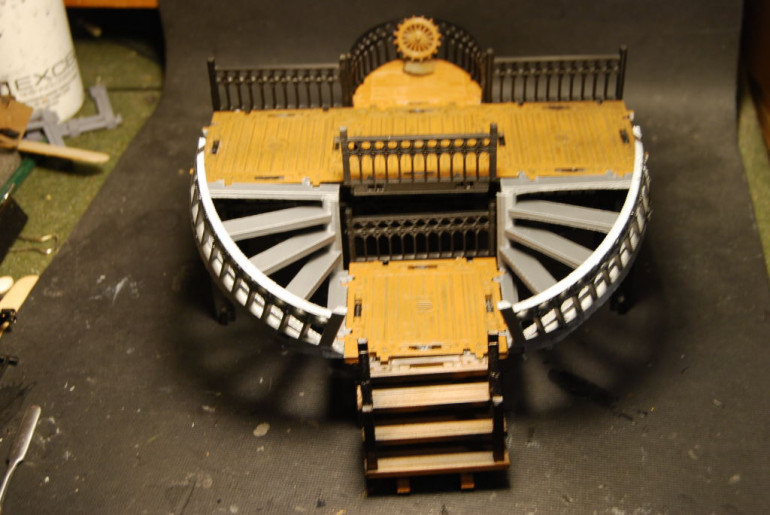

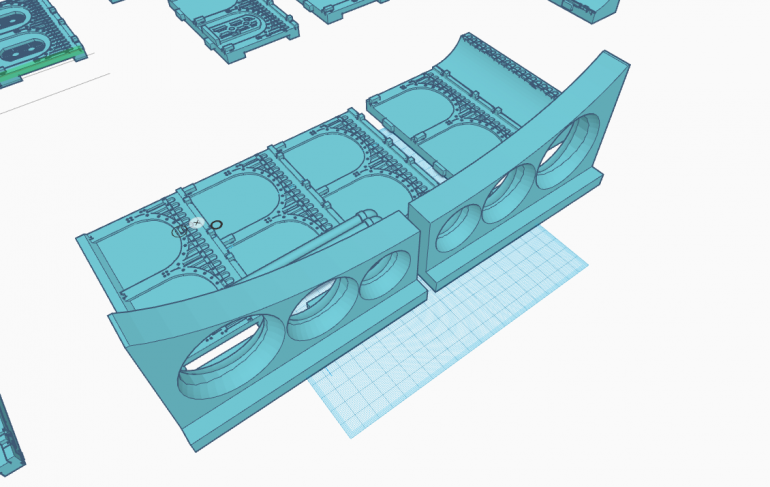

Rounded corner walkway

I started this idea about a month ago, because all the little issue i ran into it was put on hold. i was working on a lot of 10 to 20 hours prints so i would print a part weeks apart.

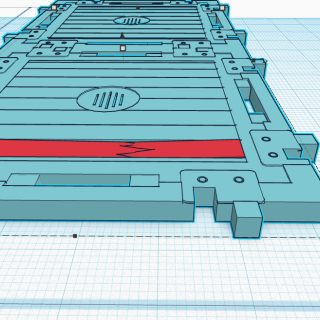

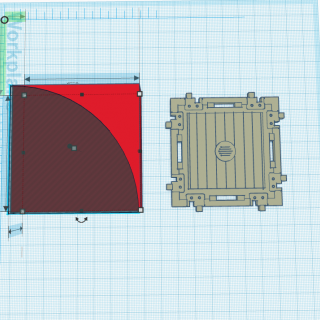

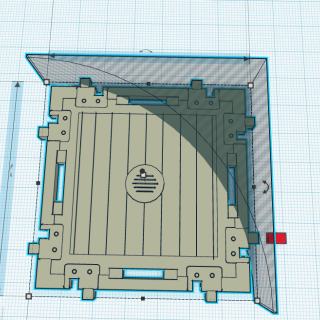

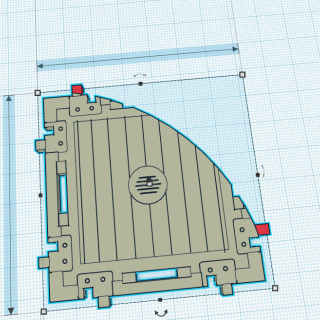

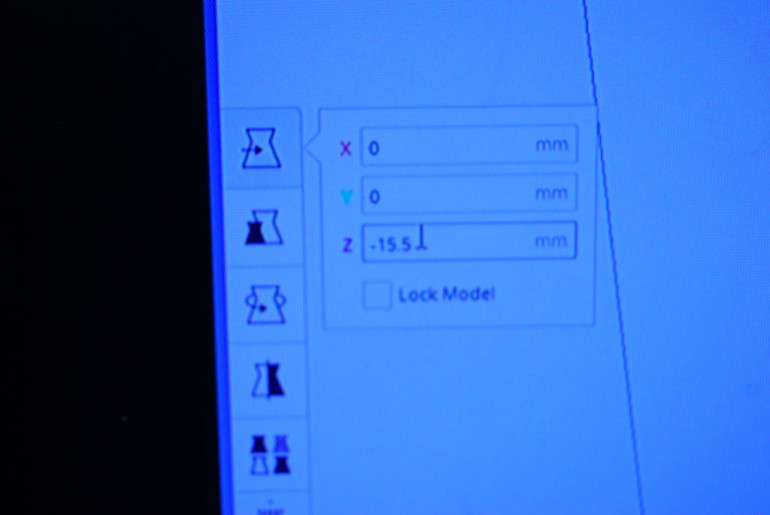

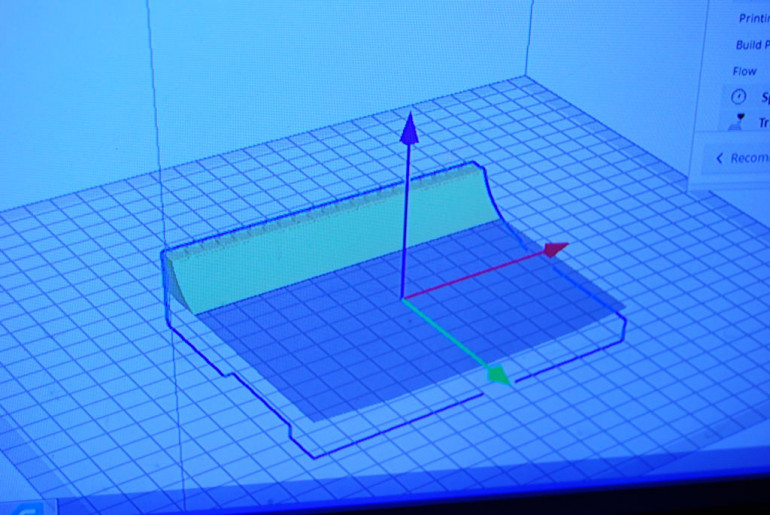

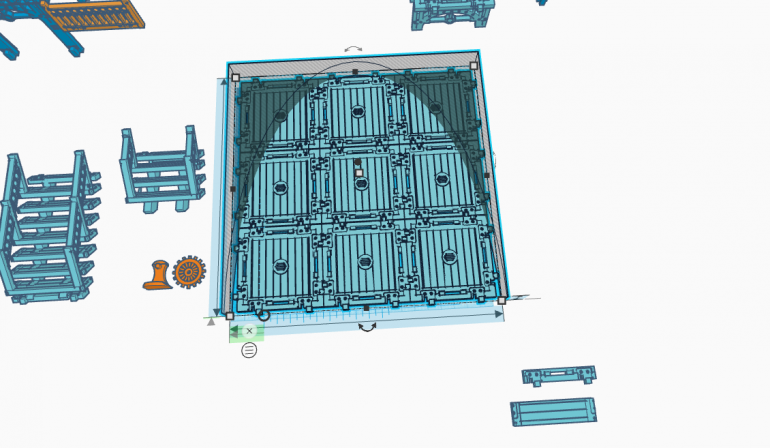

Basically i created a square box the size of the walkway then created an negative arc to remove most of that box. to get a shape i need to remove to get a nice curve. lastly i had to elongated the tabs to hold my rails. Off to the slicer and the printer.

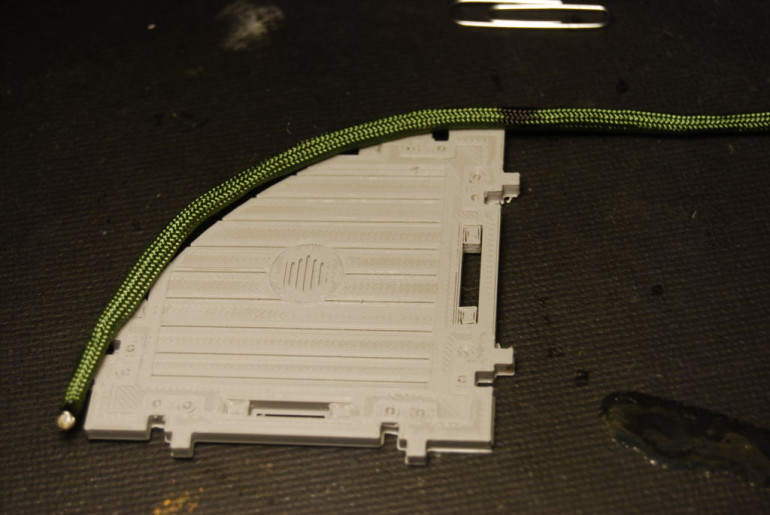

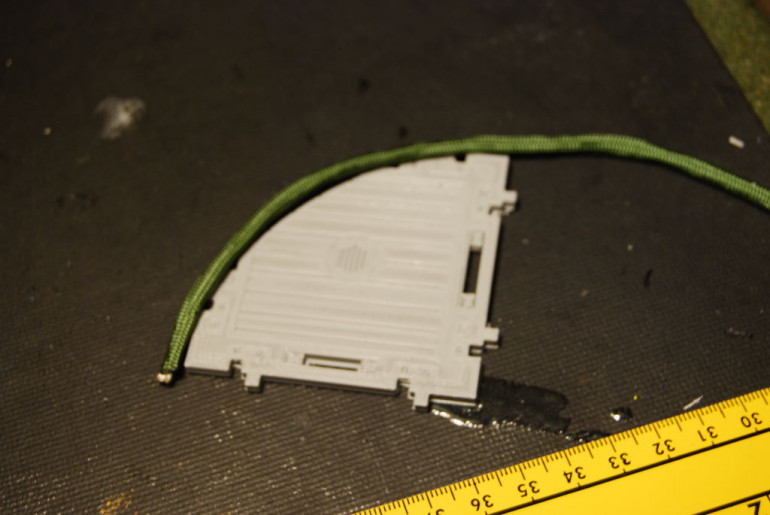

I use para cord to measure the curve. I guess there is some formula to calculate this, but this method work for me

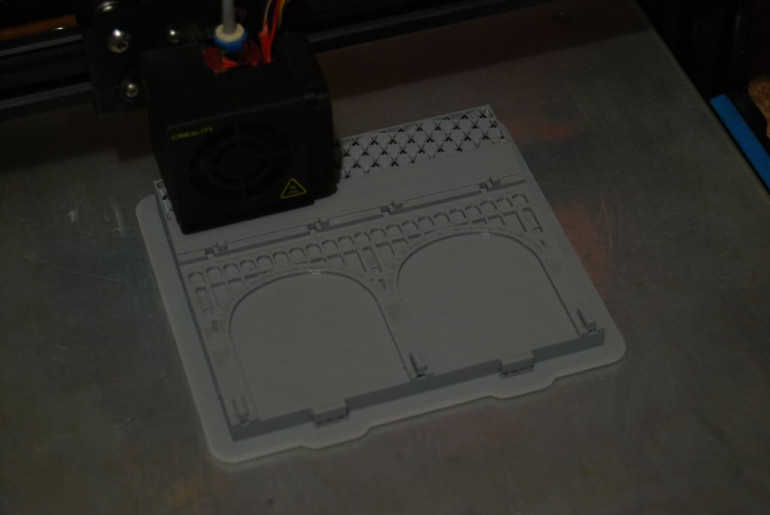

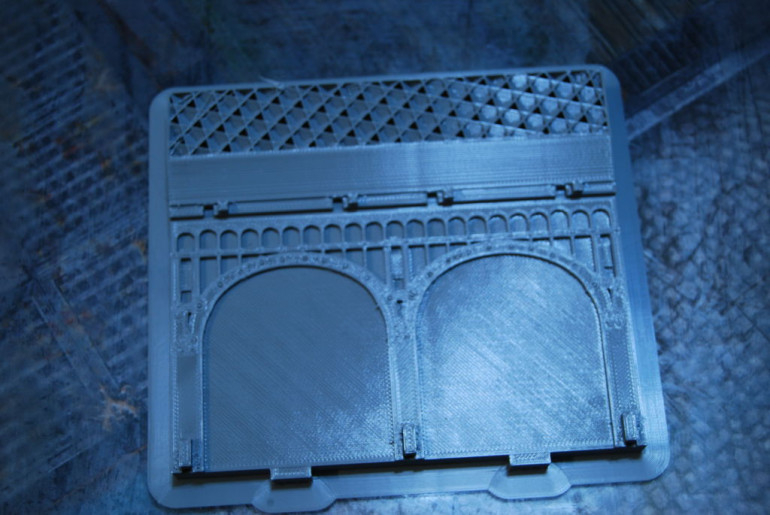

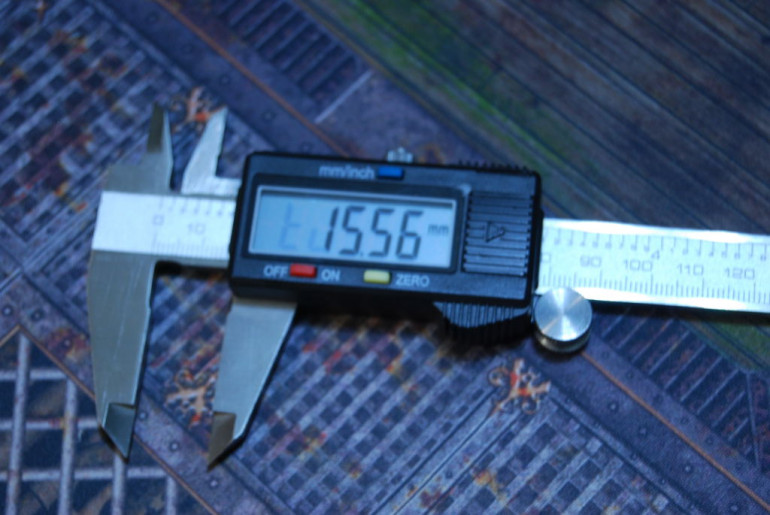

I use para cord to measure the curve. I guess there is some formula to calculate this, but this method work for me In Tinker CAD, i had to splice two rail images together and get 106mm length of rail that match and then i shrank it to 105mm.

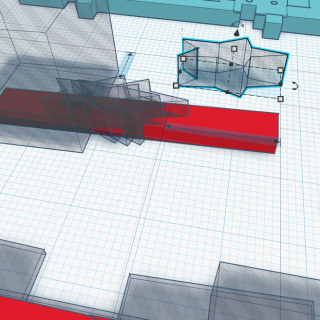

In Tinker CAD, i had to splice two rail images together and get 106mm length of rail that match and then i shrank it to 105mm. First mistake made the creating the arch 105mm in length and it bends pass the edge of the corner walkway. I would shrink this to 90mm.

First mistake made the creating the arch 105mm in length and it bends pass the edge of the corner walkway. I would shrink this to 90mm.Power outage

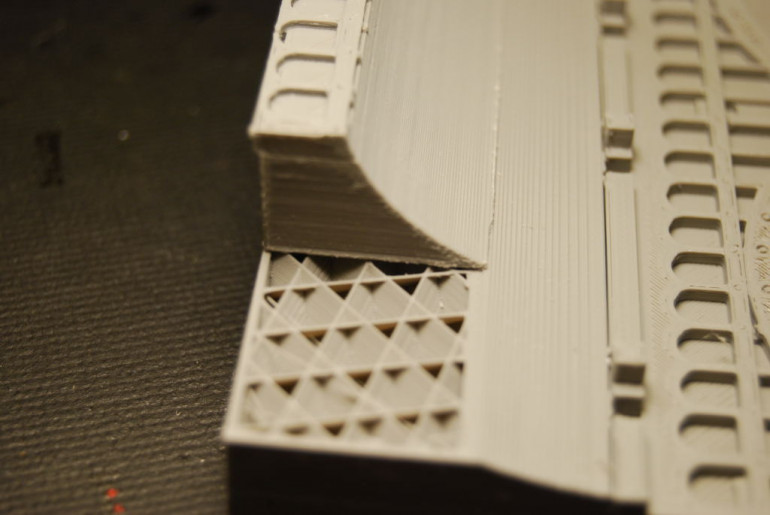

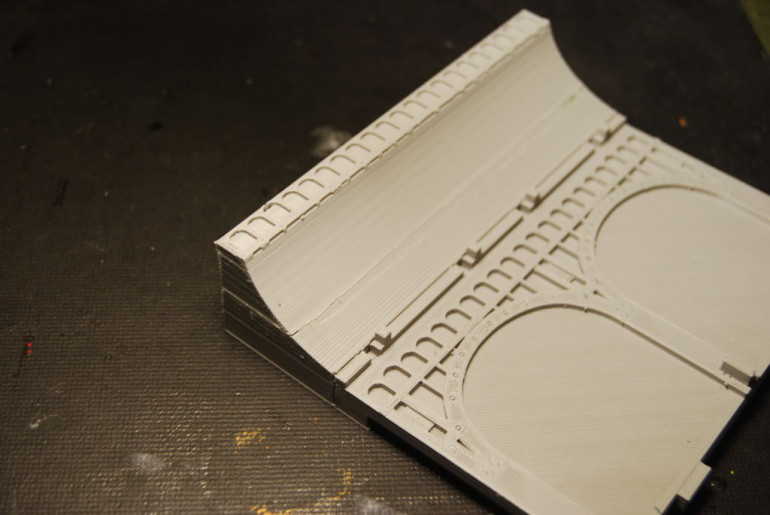

Time to time i have fail prints. This one was from a power outage during a thunder storm (Its very common this time of year). I do have a battery backup but it good for only 30 minutes. Most of the time i have to reprint the part, but in this case i can fix this fail print.

Accident happen

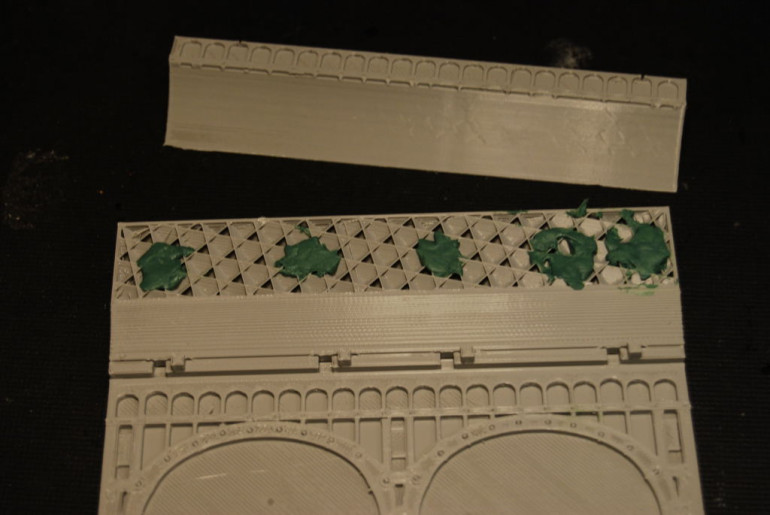

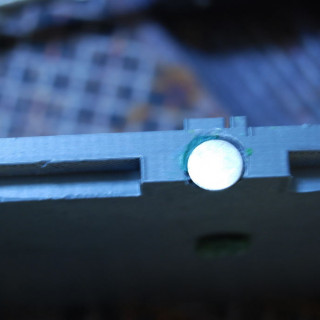

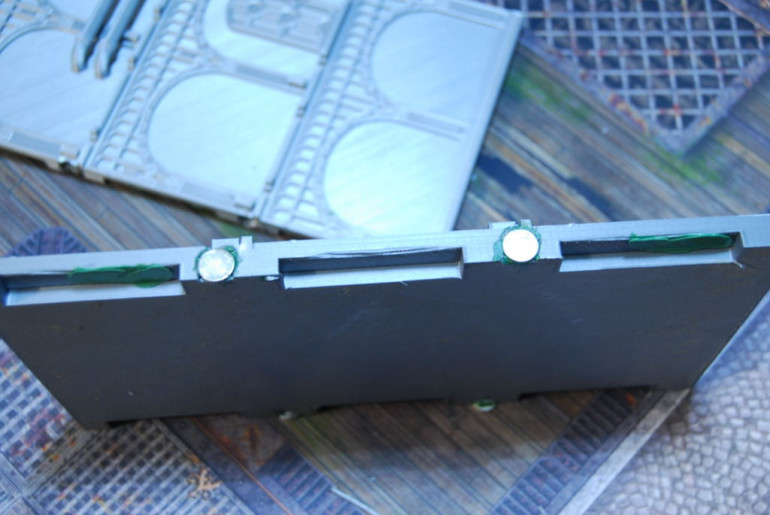

Last week i bump my gaming table a little to hard and topple my hanger wall and had one of them snap. I spent the rest of the week and weekend fixing the interior walls to be more stable. I decided to add some 1 cm magnets.

I found some 1 cm x 1 mm round magnets which match a 3/8 drill bit i had. I use the drill in reverse to melt the PLA plastic i used to print with. Then i added some green stuff to fill and keep the magnet flush.

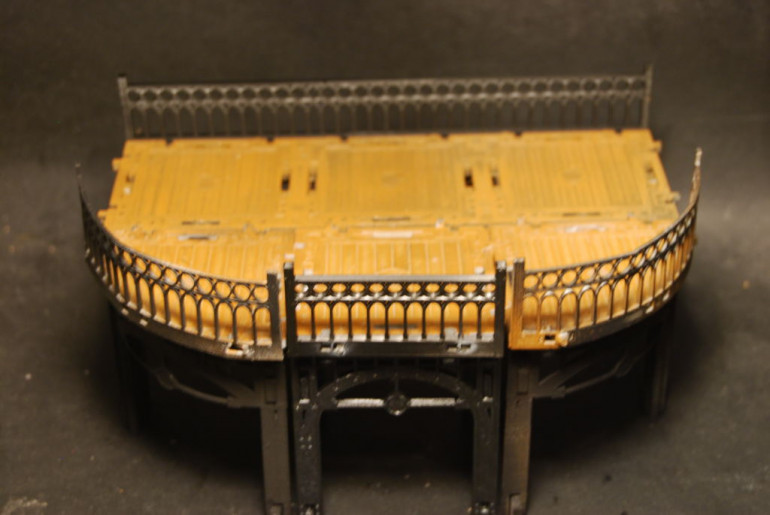

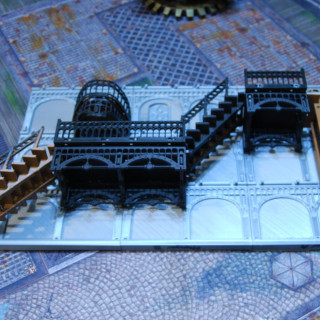

Steampunk Bridge

This is what i would image a steampunk bridge to look like :).

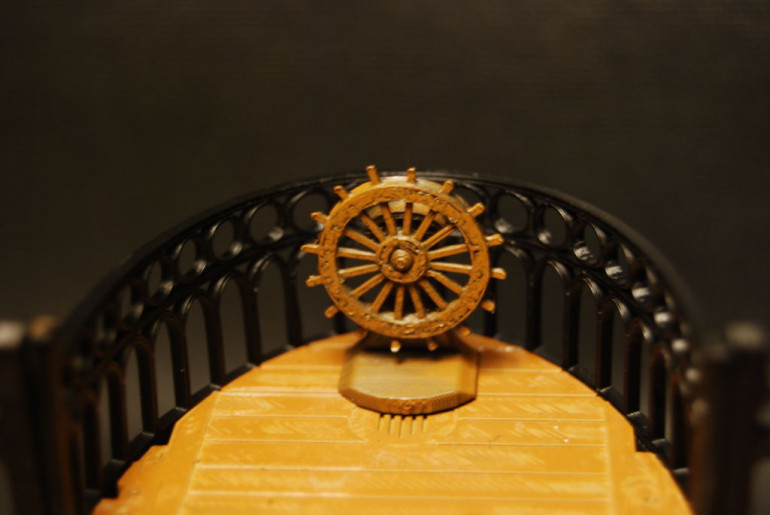

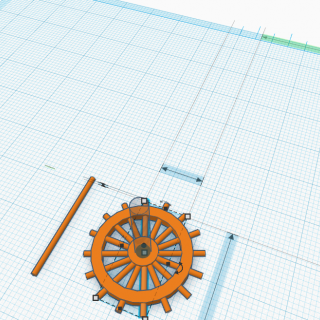

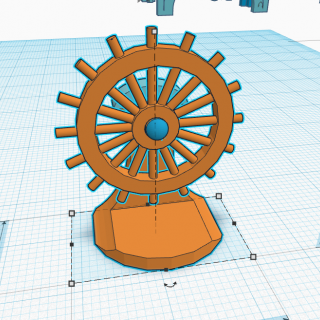

Steering wheel

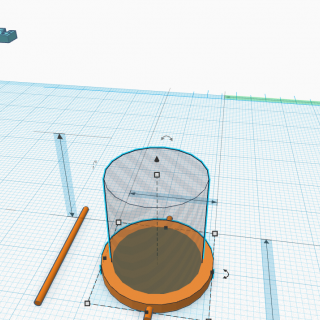

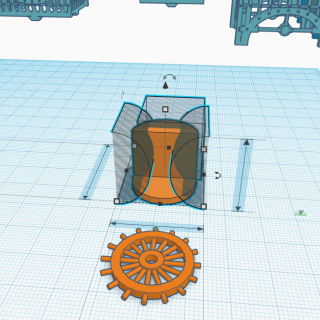

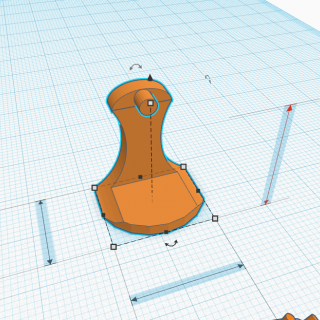

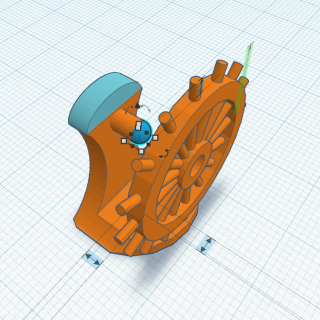

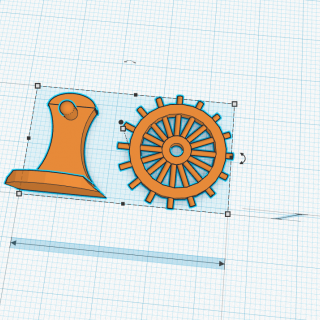

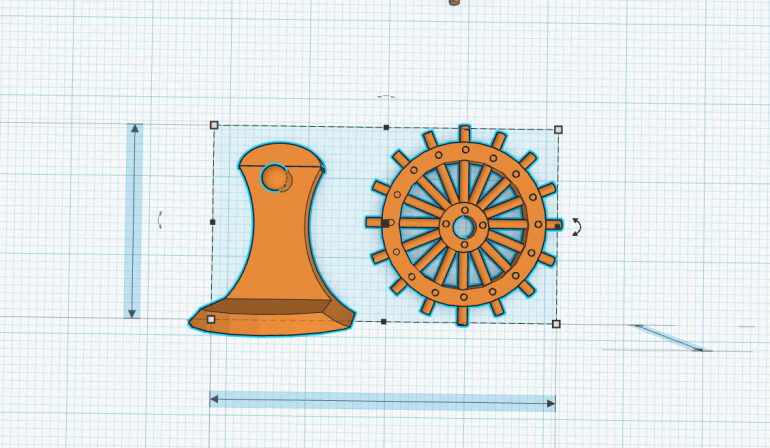

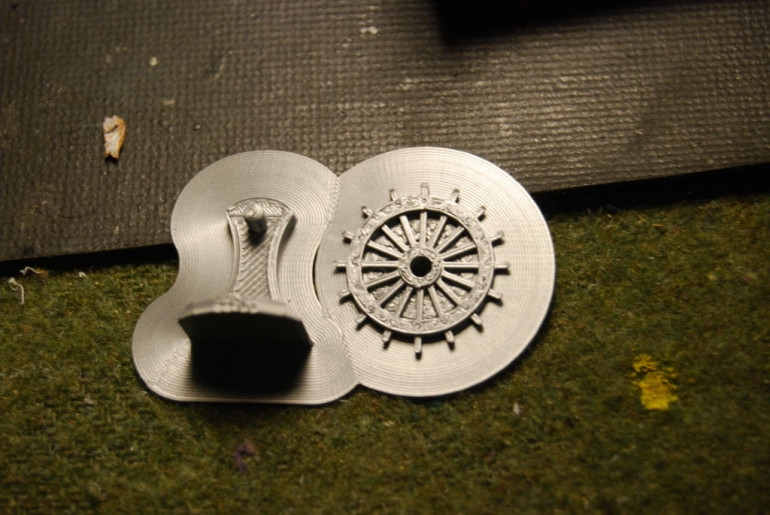

I basically created 2 cylinders one for the yoke and the other for the body. i rotated the 1mm x 1mm x 24 mm yoke 90 degrees and center it with the body as you will see i was not quite center top to bottom and as i copy the yoke and rotated it 22.5 degrees it was off center. The next step was to create the center point of my steering wheel. The wheel is done for now next i created the the podium using a cylinder base and proceed to remove various shapes to create a design i liked. Lastly i added the center axis and did a test print for size.

I am happy with the size and went back to correct my centering issue.

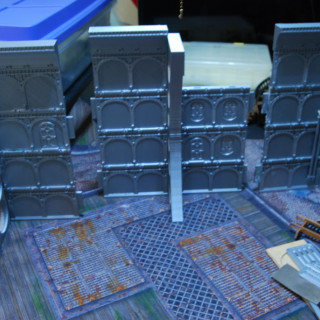

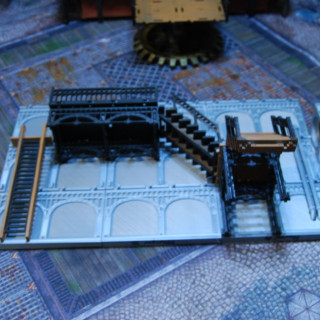

What i have done so far

I am waiting for some filament to arrive. After i have complete a few test walls and I started playing with some possible layout.

![Warcradle Studios Reveal TINY New 10mm Festive Marker! [Updated]](https://images.beastsofwar.com/2025/11/christmas-kyle-main-600-338.jpg)