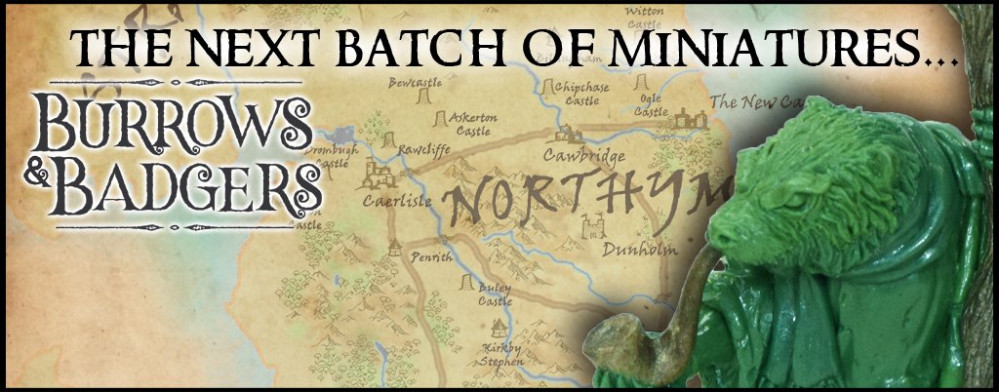

Burrows & Badgers – getting back to sculpting!

Recommendations: 534

About the Project

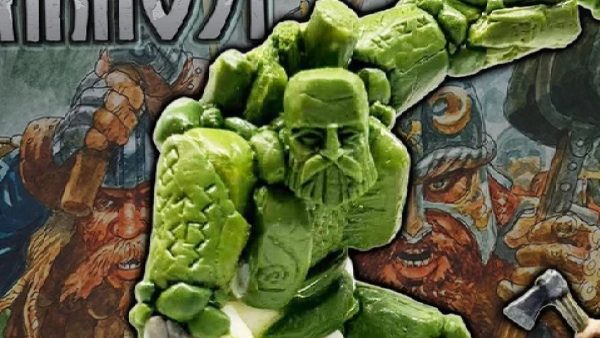

We're getting ready for a new Kickstarter for another batch of Burrows & Badgers miniatures. So there's lots of sculpting and planning involved... I'll post as much of it as possible here.

Related Game: Burrows & Badgers

Related Company: Oathsworn Miniatures

Related Genre: Fantasy

This Project is Active

Feet, legs and tail...

Next I started on the lower body, with the feet. Again, a lump of putty was pressed into place on the front of the foot armature, and another added behind to form the heel and ankle joint. Lines were cut in with the Wax 5 for the toes and claws, and the whole thing smoothed and tidied with the Clay Shaper. It’s a pretty simple process, but you have to be gentle and take your time.

I continued working up the leg; pressing putty onto the armature, then roughing in the fur pattern. I then spent some time gradually refining each separate bit of fur, with the sharp end of the Wax 5.

I did the same with the other leg; then used the same process to do the tail.

Once the legs were fully cured, I mixed some more Brownstuff and finished the badgers’s staff. The sculpt looks a bit odd at this stage, but from here on will start to take shape fairly quickly, as large areas of clothing get added.

Final posing decisions and hands...

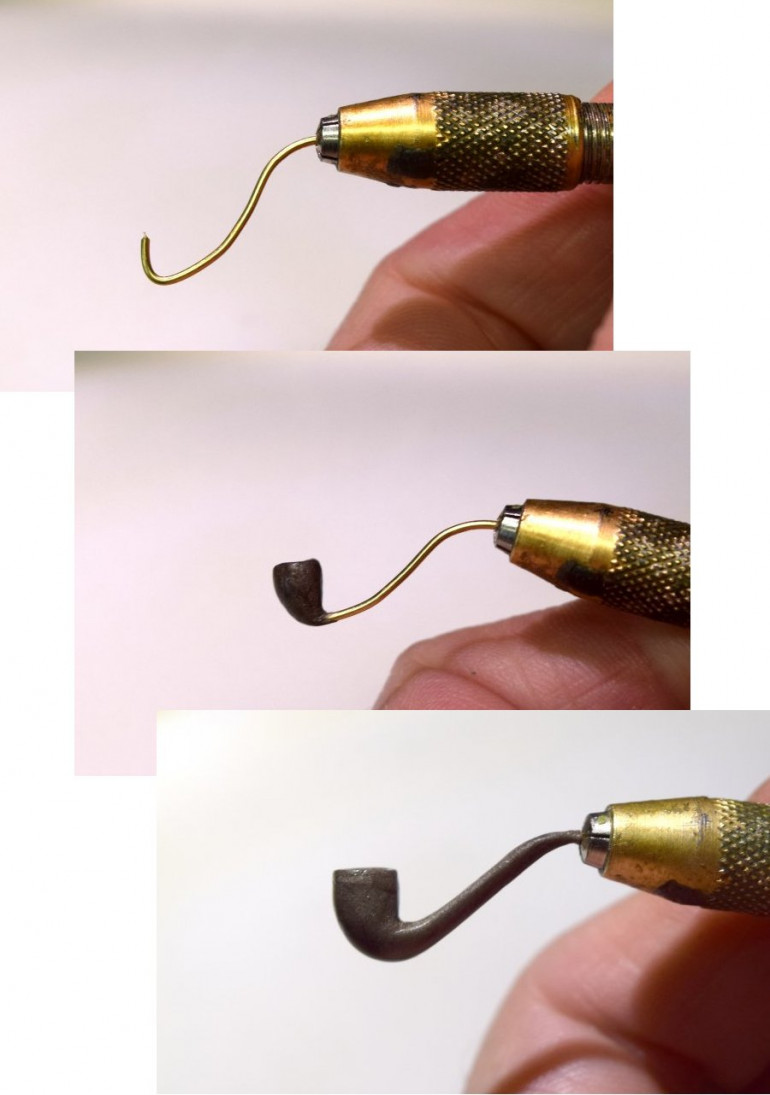

At this point, I got nervous about the pose again. I thought the pipe would be OK, but I thought he looked good with the hand down too. In the end, I decided on the pipe, and started filing it down to reduce the size and get it smooth.

With the pipe filed down, I glued it to his hand with superglue. You have to be careful with superglue; many mould rubbers react badly to it, and it liquifies and foams badly under the heat and pressure of the vulcanising process. In this case though, it would be fine, as the superglue would be entirely encased in putty, so not anywhere near the mould surface.

I moved onto sculpting the hands; I pressed a lump on putty into place, then cut lines in for the fingers, and used the Clay Shaper to gradually refine them. Then I cut a line across for the claws, and continued gently smoothing the fingers, shaping them to show joints and knuckles. Finally I added a thin sausage of putty for a thumb.

The other hand followed the same process.

Fitting the head and the pipe...

Once the head was fully cured, I drilled a hole into the badger’s body, and fitted the head armature’s wire into it, and bent it around until I was happy with the position.

With the head in place, I test-fitted the pipe, which turned out to be way too long to fit between his hand and his mouth… so I made a shorter one.

Of course, a little pipe doesn’t take much putty, and I’d mixed up far too much. So rather than let it go to waste, I used it to start on the badger’s staff. I rolled the putty into a thin sausage, pressed it onto the staff armature wire with my fingers, smoothed it with he Clay Shaper, then used the Wax 5 to cut in lines for the wood grain. I only had enough putty mixed to get about halfway down, but that was OK – if I’d done the whole thing, it would have made sculpting the feet harder.

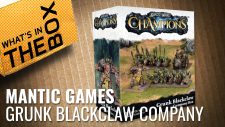

On with his head!

Next, I sculpted the badger’s head. I took the cured head armature, and added a couple of blobs of fresh putty for the eyes. Then I added two more blobs to form the cheeks; and a thin layer over the top of the head. Next I added some larger bits of putty to the back lower quarters of the head, to form the bulk of the jaw. I blended this all together using the Clay Shaper.

Then, using the sharp edge of my Wax 5, I cut in a line for his mouth, and marked in the shape of his eyes, pushing the putty up and down to form the eyelids. I used the Clay Shaper to smooth and refine the eye area, then added a couple of lumps of putty for ears, and a little more bulk to the back of the jaw area. I continued to tidy and refine the head, and added a tiny bit of putty for the nose.

Next, I used the blunt end of the Wax 5 to pull the putty downwards to rough in the fur, the used the sharp end to refine each section of fur to add definition.

Adding some bulk...

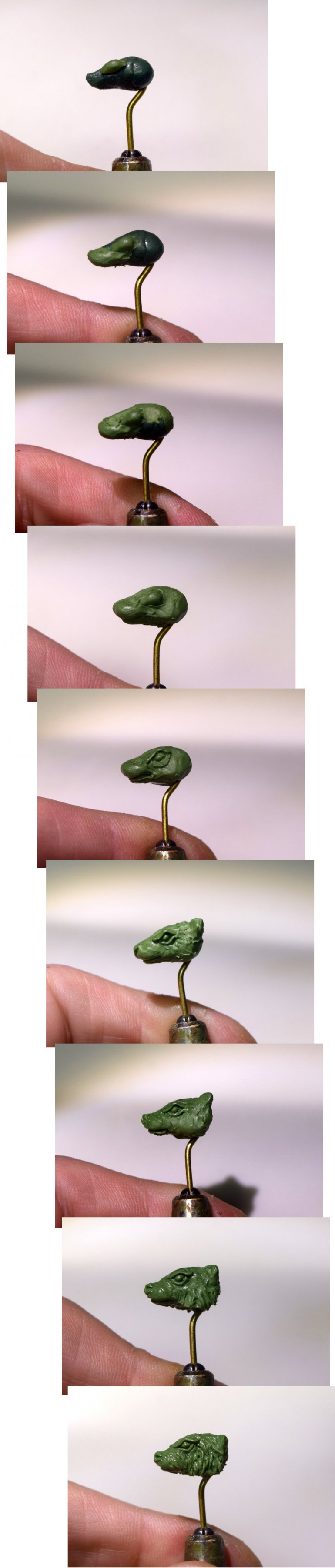

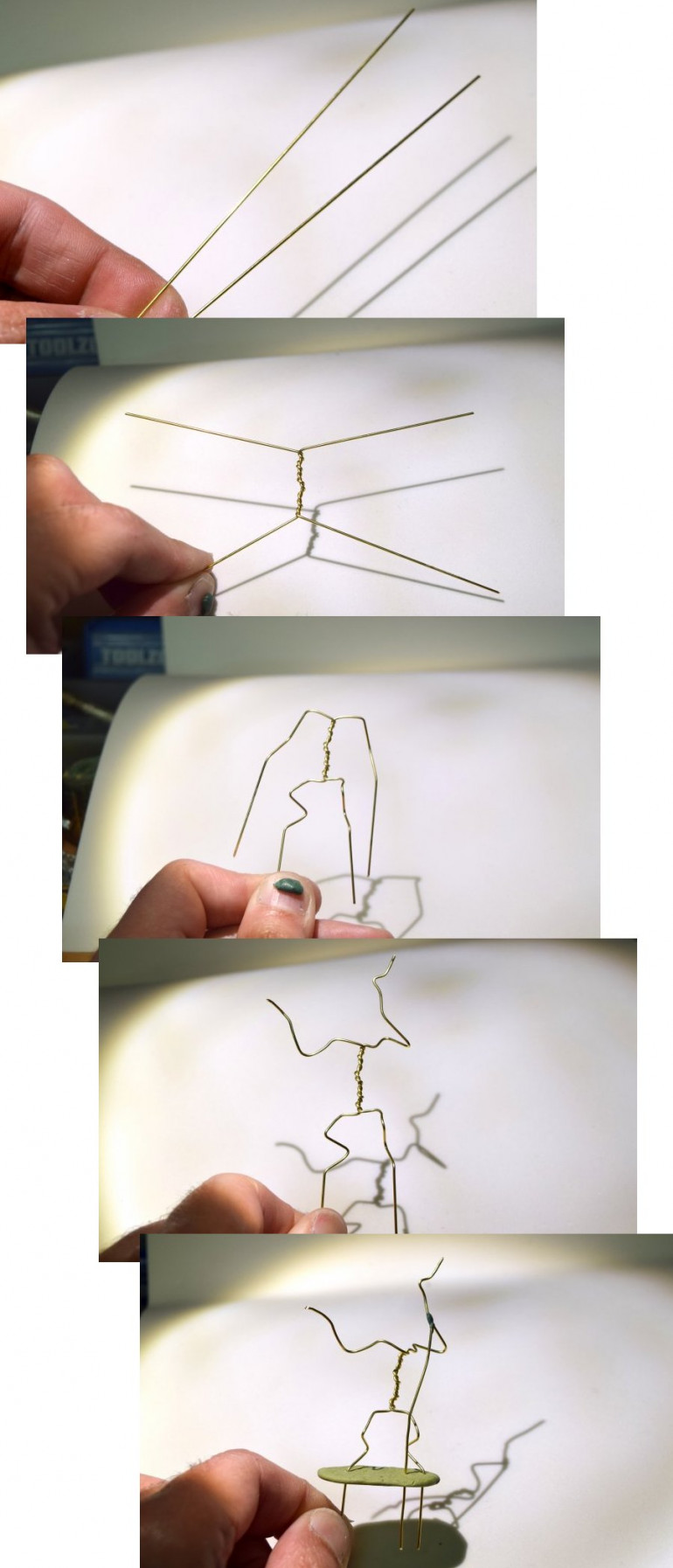

I attached the armature to one of my sculpting blocks next. The sculpting block is just a couple of pieces of wood, held together with a nut and bolt. Many sculptors use corks instead, but I’ve always found them to be unstable, and a part-finished sculpt falling over is definitely something you want to avoid! The sculpting block is a much more solid, stable way to hold the armature.

I started bulking out the body armature at this point; I kept it quite rough, because it would all be covered by fur and clothing. I added a piece of wire for the tail at this point. I also started thinking about altering the pose; I thought maybe smoking a pipe would be better than pointing, so I bent the arm to a ‘pipe-holding’ position.

Obviously, this meant I’d need a pipe! So, I bent some more brass wire, and mixed some Brownstuff, and made the rough shape of the bowl, let that cure, then sculpted over it to complete the pipe.

Armatures and stuff...

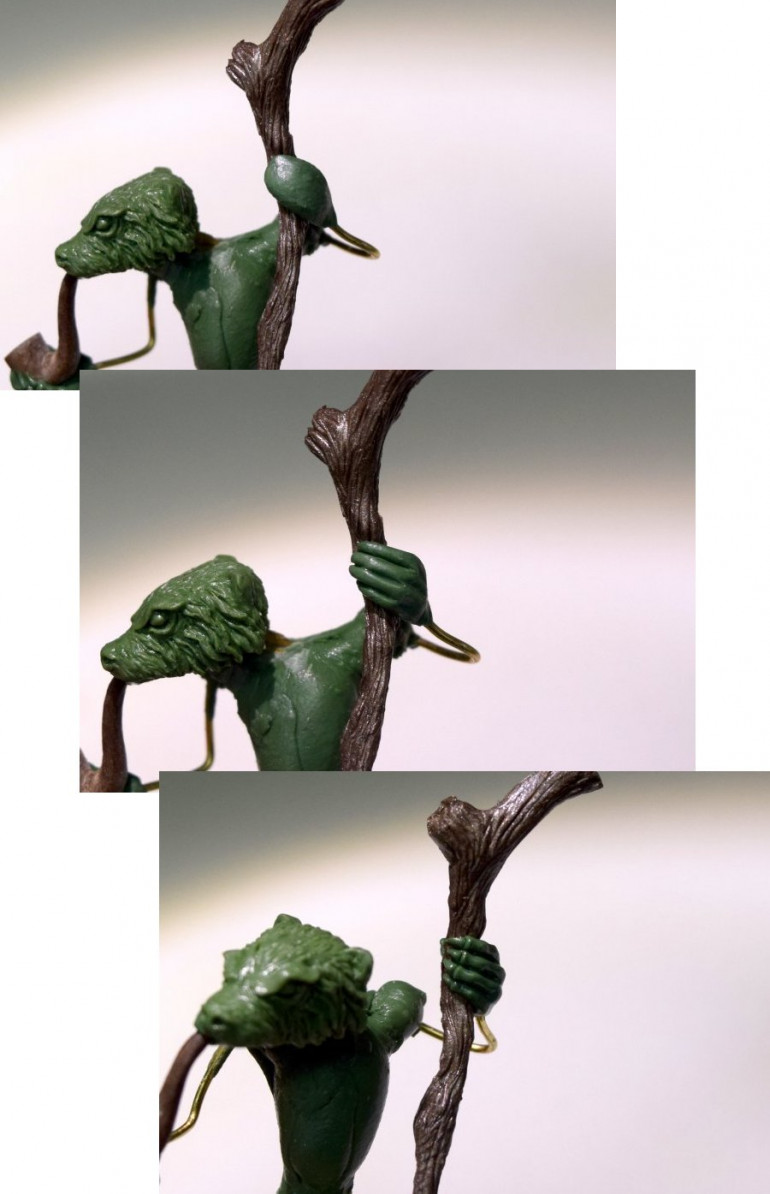

I started the sculpting process by bending some brass wire and attaching a blob of Greenstuff, to provide a basis for sculpting the head. This was left to cure.

Then, using .51mm brass wire, some clippers and some pliers, and started making an armature; I twisted two lengths of wire together, then bent the limbs to shape, and posed the armature. At this point there was no wire for the tail; I usually add that later.

I also attached the armature to a base at this point; all the Burrows & Badgers miniatures have integral bases, which I make using equal parts of Greenstuff and Milliput. This makes the base tough without being brittle; otherwise it can bend or snap during the mouldmaking process. I press a blob of putty flat on a sheet of acetate; it’s one of the few things that it doesn’t stick to!

I texture the surface with a stone, and I also press the armature’s leg wires into the base to make holes; the base can be very hard to drill through, and marking the holes first like this makes it much easier. Once the base has cured, it can just be peeled off the acetate.

Tools

I started by getting all my tools ready. I use a fairly small number of tools; a chisel point Clay Shaper (size 0), a Zahle dental tool (commonly called a Wax carver No.5, or an SG dental), an old scalpel blade stuck to a lolly stick and a piece of bent wire stuck into an old paintbrush handle. These cover about 99% of my sculpting needs; but you can really use anything you like as a sculpting tool – if it makes the mark you are looking for, then use it! In terms of putties, I use mostly Polymeric Systems Kneadatite Yellow/Blue, more commonly known as Greenstuff, which is a two part epoxy putty, originally made for plumbers to fix pipes! I also use Brownstuff, from the same manufacturer, which is slightly less elastic and can be filed and sanded. I find Milliput to be useful as well, mostly for bulking out large pieces, or making weapons and bases.

Getting back to my real job...

When people ask me what my job is, I tell them I’m a sculptor. But to be honest, other stuff keeps getting in the way… there’s only myself and my wife Jo running Oathsworn, so everything from games design to order packing needs to be covered by one of us. And we’ve been busy lately, which means that I haven’t sculpted anything since the end of January.

So, after a six month break from sculpting, I wasn’t even sure I’d still remember how to do it…

But we’re a miniatures company, so we need new miniatures. Time to dig out the putty!

The plan was to do another Kickstarter to fund a set of new models; generally we do ten to fifteen at a time. I started by making a list of potential ideas:

1. Squirrel archer, male. Rogue-ish, Robin of Sherwood type.

2. Mage, female. Either fox or otter, either will work for the pose I have planned.

3. Badger mage, male. Old, wizened, scrawny, robes.

4. Beaver, male. It’s been suggested that the beaver should be a mage, but I’m leaning towards a ruffian / brigand leader type.

5. Massive Raptor – either Osprey, Red Kite or Buzzard.

6. Massive Hound, male – Staffordshire Bull Terrier probably, or maybe a Border Collie instead. I’m picturing armour and a tabard / surcoat.

7. Weasel, male, with a blunderbuss. Similar to the pic on p.38 of the Burrows & Badgers rulebook.

8. Cat, male. Landsknecht style. Maybe a two handed sword, maybe a halberd?

9. Wildcat, female, in Highland Clan gear.

10. Shrew or Squirrel, female, in Highland Clan gear.

11. Mouse, male, helmet, armour, surcoat and crossbow.

12. Kestrel – Not certain on this one; I have a pose in my head, and if I can make it work, it’ll be great. If not, I’ll pretend it never happened, and sculpt a different bird instead…

13. Frog of some kind – probably a soldier/fighter type.

14. Bat assassin.

15. Shrew-zerker, similar to the pic on the last page of the rulebook.

I thought I’d start with the male Badger mage; he’d be a big (45mm+) sculpt, and I guessed the large size would make it good way to ease myself back into sculpting.

I drew out a very rough sketch of the badger mage idea; I don’t usually do this, and given how little the finished sculpt looks like the concept sketch, that’s probably a good thing!