Build an LED Arch Hobby Light

Recommendations: 34

About the Project

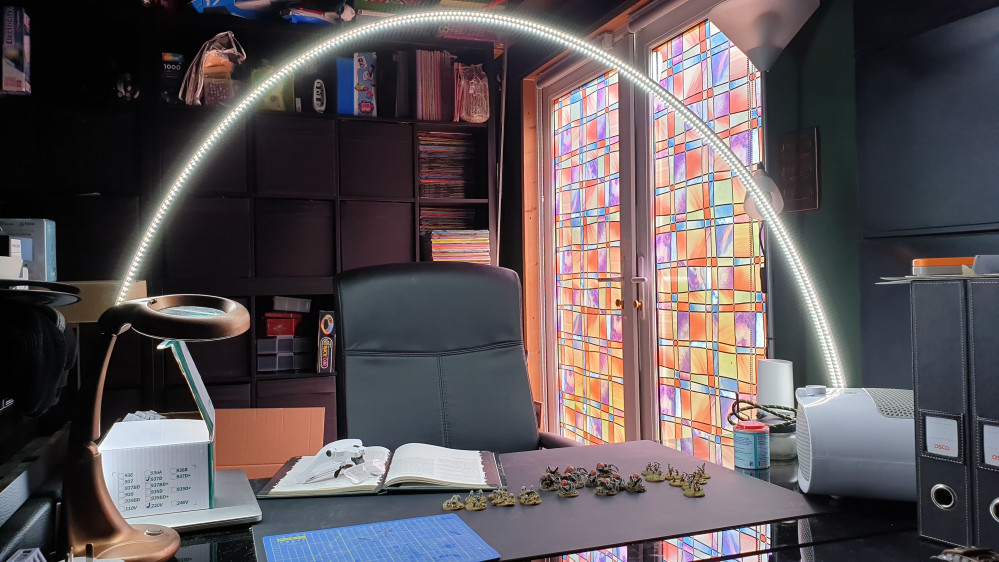

I want better lighting on my project desk, so I have opted to build an LED arch light for maximum light and maximum shadow reduction.

Related Genre: General

This Project is Completed

Something to create the Arch

So I took a trip to the hardware store. The please to go to is the tiling section and have a look through the PVC Tile Trims. You will find all sorts and all colours. Most will be flexible enough to create an arch.

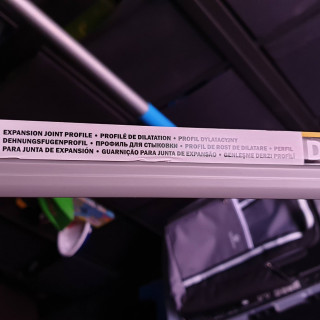

On this particular day, I discovered these joint profiles, honestly I’m not sure what they are for (I think they are a flooring product of some kind)

But they were reduced to £2! – So I picked up two of them in case I decide to create two of these arch lamps.

The LEDs

I set myself a bit of a wishlist on the LEDs as they do come in all sorts and varieties.

I wanted a simple setup with a single colour temperature – day light. You can, of course, get sets that will vary the light temperature from warm light to daylight, but often they use multiple varieties of LED on the strip so at any one time you are only utilising half the LEDs. Because I want this as a work light I’m not fussed on being able to change that.

You can also get other systems such as Philips Hue that will let you play with colour, I thought hard about this and although I’m a big fan of Hue again I opted not to bother and put all the tech into a simple setup without the bells and whistles that honestly I would rarely use in this use case.

Power of LED’s is another consideration, in this instance, I’ve opted for 24v as the electrical contractors tell me I will, in fact, get more light from them.*

You can also see that the led density on the strip is quite high, and it comes with a 3M self-adhesive back.

A word on ‘local experts’…

One area of my life that has been a real letdown is ‘local experts’ for some reason 99% of any that I have ever worked with have unfortunately been bullshitters.

So as it turns out there are differences between 12v and 24v but it has little if nothing to do with brightness.

Driving the LED's

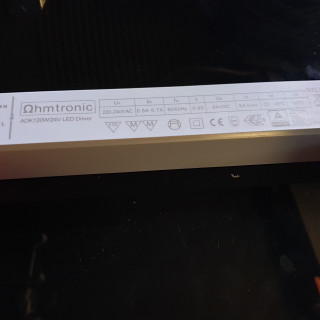

To power the LEDs you will need a driver. There is cheaper ways of doing this (and simpler) just buying one of the little kits with a plug from Amazon, but I wanted to test the difference here if you went down a more ‘electrical contractor’ type route to see if the little bit extra you spend on the semi-pro stuff actually makes a difference.

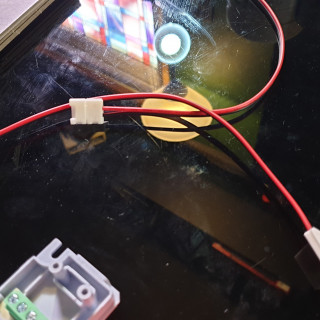

So here is the 24v driver and some of the connectors I plan to use.

Designing a table clamp

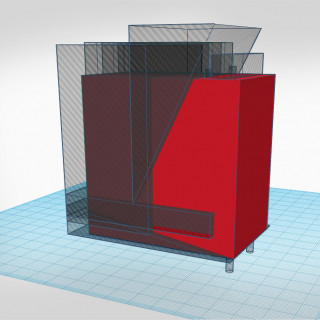

Next stop is into Tinkercad to design a table clamp. I need a clamp that can fix to the glass desk I use as a hobby table.

And it also needs to fit the profile of the flexible arch material.

In both cases they rock in at just under 10mm

Tinkercad

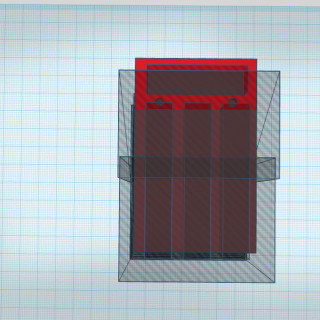

I am no expert at tinkercad. But I tend to try and think of it as a subtractive modelling system – at least in this case. That’s where I started with a solid block and then added shapes that I wanted to remove from its volume.

It takes a little getting used to, but after a while, you will add a bunch of shapes to subtract from the whole – and the whole time trying to take into account where the forces are most likely to exert themselves upon the clamp.

You can then combine everything to see what it will look like.

Building some supports in.

When printing this on the resin printer there will be a part that will need a few extra supports to stop it collapsing in on itself during printing. Rather than messing around with the slicer I just added 1.5mm pillars (Marked in orange) to that section in the model. If it works I will then basically scrape these bits out after it prints.

Working in the slicer

When I initially built the model the part that slides under the table was a good bit longer, but upon slicing I saw it had become a 14hr print. (resin printers time is based on the height of the model).

I thought that was overkill and the way the forces would act upon the clamp it wouldn’t be necessary so I tweaked the model and what you see here is about a 7hr print (per clamp.)

You will notice some little holes in the clamp. I added these to run some of the electrical components through.

And Now Time to Print...

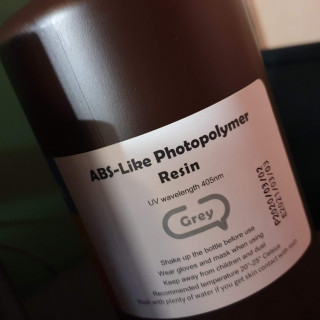

So Im going to print this on an Elegoo Mars resin printer. Mostly because its the only one handy. I’m sure it would work just as well on an FDM, you could print more of them too and they will print quicker. (My FDM is in the studio printing out ear protectors for local health workers so I’m not planning on disturbing that!)

Anyway, I really like the smooth finish from a resin printer so provided the finished print can take the stresses this should be good. Also, it will be interesting to see if the tolerances are too tight or loose in the final version.

I’m using a grey ABS-like resin for this. It’s my favourite so far because when you are printing models it looks like a model you would buy. That and I’ve found the results more predictable than some of the translucent resins I have tried.

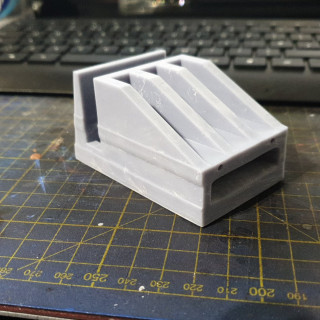

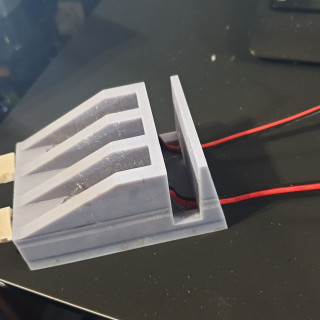

First test pieces are out

So I printed two test pieces each one took just under 8 hours to complete. There is a strange deformation in the print but I will deal with that later.

The holes for the wiring have also deformed a bit so I will drill those out on these pieces just to keep the process moving so I can pull together a rough concept.

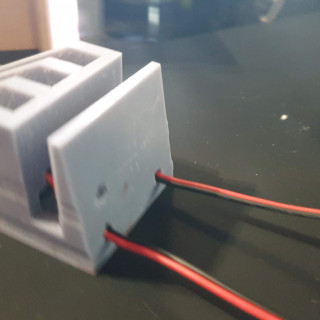

Wiring it up

I then wired it into the 24v power block. Being careful to keep my +s and -s right!

Applying the LEDs

I found that adding the LED’s to the strip must be done while it is bent in place. Otherwise if you add them when it’s flat they curl up on you when you bed the strip.

For this concept piece, I decided to add two strips, for an ultra amount of light. So in total, I used about 5m of LED strip.

Connect the trips to the power

This I found to be VERY fiddly. The little connectors seem like a good idea but in practice, they are not very effective at all. But for the purpose of testing the idea, they will do. But I’m going to have to rethink this as I’m not happy with them at all.

But…

Lets switch it on and see what happens!

TaDa!!!!!

It’s alive!!!

Ok I’m happy with that as a concept, but the wiring is not what I want… I’m going back to the drawing board to rethink how I’m doing this. I may need to take a leaf out of @blinky456 book and use a soldering iron! Which reminds me – he left one here for us to use mmmmmm….. am I brave enough….

Lets start by re-wiring.

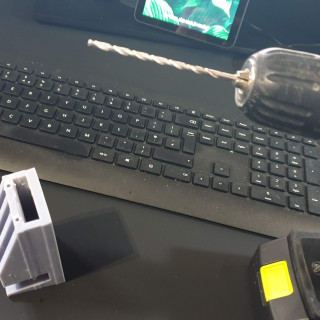

OK, so I need a better wiring setup. So I’m going to have a go at soldering. I’ve already drilled into my finger on this, so hey whats a few burns for the aspiring DIY guy eh!

First things first I’m going to change the flex, so I can make the connection to the power block longer (this will give me a bit more flexibility).

I found this relatively light 2 core laying around.

Our mate blinky left behind a soldering station, so I have nabbed that and will fire it up to see how it works!

Well, this turned out to be tricky! Trying to hold two bits together while also trying to hold a soldering iron and the solder is no easy task.

But it’s on, its not pretty but it is soldered at least! I will have to read up on soldering techniques and give this some more practice. Maybe I need to buy a set of those helping hands things? or a little set of clamps.

Suggestions welcome folks!

OK now I’m going to join the wires at the other end and put a drop of solder on them to lock them together and screw them into the power block

And finally to add a bit of T-REX Tape around the join to keep it a bit tidier…

But now I’m gonna have to redesign the mounts to take into account the extra thickness!

OK Back to TinkerCad!

Step 3 - While I'm at it I'm going to tighten the glass table slot as well to see if I can make it a tighter fit.

Step 3 - While I'm at it I'm going to tighten the glass table slot as well to see if I can make it a tighter fit.As you can see above, I have adjusted its orientation in chitu box for printing. My thoughts are that there will be less force on the FEP etc printing it at a slight angle and that ‘might’ stop the strange distortion that’s appearing in the prints I have done so far.

And back to the printer once again!

8 Hours…. mmmmm…. That gives me some time to think about how I’m going to switch the damn thing on and off – as there is no power switch!

I’m thinking a smart home solution could be good here…

Disaster Strikes!

Broke from the supports - I reckon that over the course of the print the surface area connected to the fep film exterted too much pressure onto the supports and they weakened as the print progressed.

Broke from the supports - I reckon that over the course of the print the surface area connected to the fep film exterted too much pressure onto the supports and they weakened as the print progressed.These things happen…

But in the words of Bob Ross they may always turn out to be happy little accidents. So I washed off what printed of the component to get a look at what it was turning out like.

First thing to notice is the strange distortion is still present in the print so that's gonna require some more deeper research.

First thing to notice is the strange distortion is still present in the print so that's gonna require some more deeper research. You can also see some warping to the back of the component where it attached to the supports that attach to the build plate. This is quite common in larger prints I have attempted, and again is going to require some research into how to reduce it.

You can also see some warping to the back of the component where it attached to the supports that attach to the build plate. This is quite common in larger prints I have attempted, and again is going to require some research into how to reduce it. Interestingly enough of the component has printed to make me want to see if it might work like this. It would be much lower profile than my design and I'm keen to see if it fits to the glass table.

Interestingly enough of the component has printed to make me want to see if it might work like this. It would be much lower profile than my design and I'm keen to see if it fits to the glass table.So I set to work with a mini rasp to clean out and expand the arch slot a bit to accommodate the thicker wires that will feed into it.

The glass table slot just required a tiny bit of filing to remove a slight burr.

I then drilled and filed out a hole in the back of the component to feed the wires out through as the much lower profile of the table slot means I need to keep as much of it clear as possible – so moving the cable exit to the back makes some sense…

This might actually be better??!?!

I’m actually maybe preferring this, the low profile is quite slick and it actually fits really well to the glass table.

Here is a shot of the original design to compare it to.

And I name thee... HALO

So I’m going to let the rough prototype sit with me for a few weeks now to let it grow on me and give me a chance to use it to see what changes I need to make to a new iteration.

As I said it has no handy switch so the easiest option for me is to integrate it into a smart home setup (I use Google Assistant at home, while the studio has started implementing an Alexa setup for star trek style video drop-ins and a fancy video doorbell)

So I will implement the light into my setup using a TPLink Kasa smart plug.

So it needs a name to beable to interact with it. I have chosen… HALO… yup this is my Hobby Halo Light! 🙂

Now to control the light all I have to do is say…

OK Google, Turn On Halo.

![How To Paint Moonstone’s Nanny | Goblin King Games [7 Days Early Access]](https://images.beastsofwar.com/2024/12/3CU-Gobin-King-Games-Moonstone-Shades-Nanny-coverimage-225-127.jpg)