3D Printing Basics: Getting Your FEP Right!

January 13, 2024 by johnlyons

As a man who prides himself on falling down rabbit holes when it comes to looking into tanks, World War Two, military equipment and the Olympic Class Ocean Liners, I feel uniquely qualified to, today, bring you an article on the history and development of FEP. No, this is not a joke…Yet.

FEP, The Non-stick Story So Far!

But John! I hear the three of you cry. How are you going to tell us about the wonderful subject of 3D printing and the development of FEP and keep us entertained? A good question my learned friends.

I guess you will have to sit back with your favourite Biscuits Brown and cup of NATO Standard Tea and read on as I try to take you through the complex hydrocarbon forest of plastics, material science and two guys I found on Youtube during my research to find out.

What Is FEP?

What's commonly known as "FEP" in the 3D printing world is the clear film you find in the bottom of your resin tank that allows the UV light of the LCD screen to shine its merry, headache-inducing, light into the resin to solidify it in such a way that it creates the layers that build up that model you've never been able to afford for FIGHT WEAPON: FUTURE YEAR.

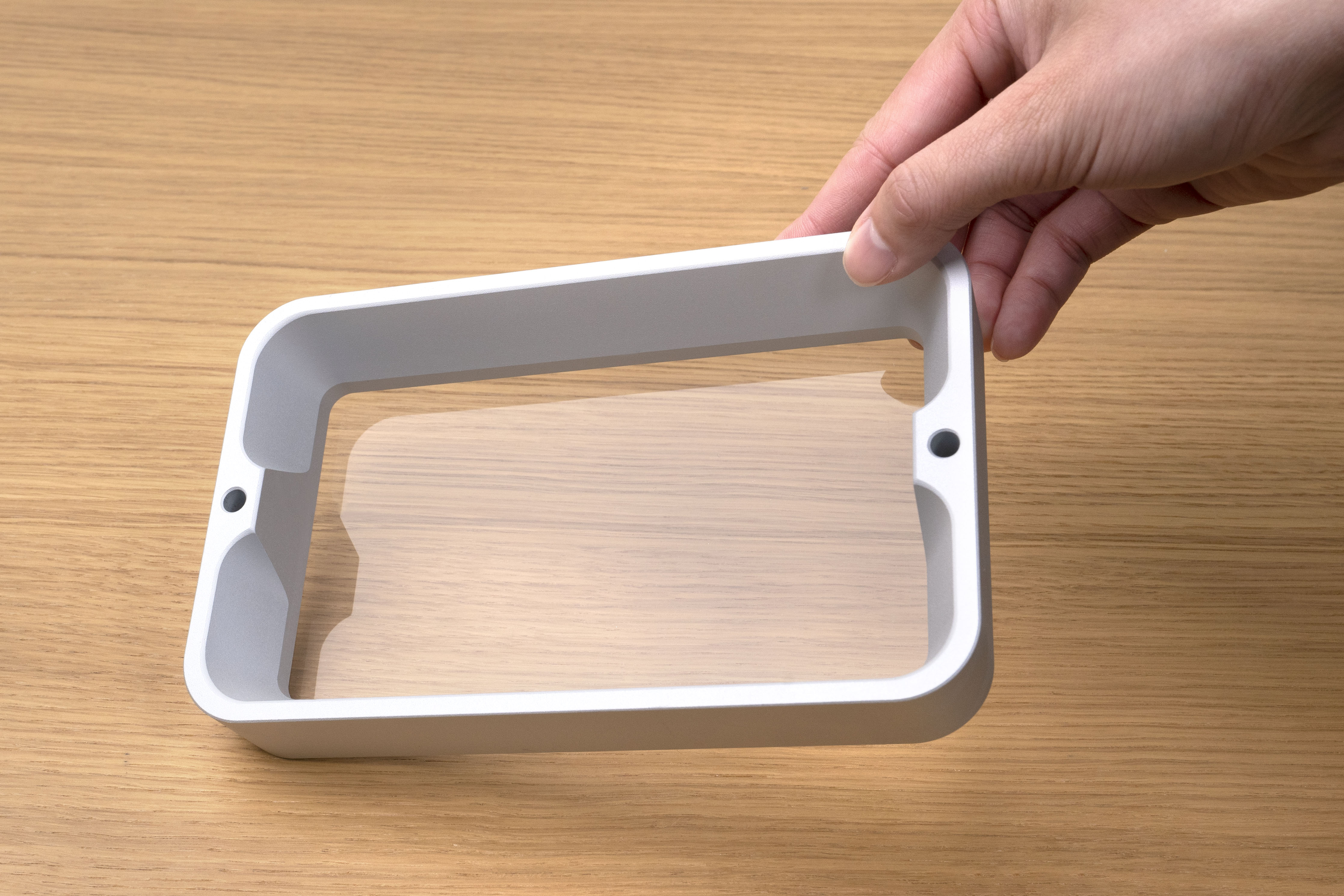

The clear-release film is part of the tank that contains the resin you pour into your printer. The tank itself can also be known as a bath, hence terms like “resin bath printing” The whole tank itself is there to contain the resin and keep it away from vital components of the machine that would not get along well with liquids! It also allows for easy cleaning of the tank after use or failure of a print!

The resin tank, and the FEP, are what we call “consumables” That means that the FEP and, eventually, the tank itself will wear down over time and require replacement. The advantage of having the tank be removable is also allowing you to, should your OCD mind need it, separate tanks for different kinds of resin. How many kinds of resin? A lot! There are so many that by the time I’d have written it all out, my tea would be cold!

FEP itself stands for "Fluorinated Ethylene Propylene" A copolymer (mix or blend of plastics) that has a high resistance to chemicals, a low rate of wear and great non-stick properties. FEP shares a similar chemical makeup as Teflon, the stuff your non-stick frying pans are always very proud to advertise!

Any clear polymer material based on Teflon can make for an ideal release film for your resin 3D printer, but it seems that FEP, itself, was the first material to come out as a release film for 3D printers, even though it's not a new material, being part of a family of copolymers developed by DuPont in 1956, and not the only one available.

Now that we know the basic properties of what makes an effective release film (that being its non-stick and high wear resistance), we can look at what other materials are out there and see how the industry has used other materials for the same role and which one is, possibly, the best choice for you.

What Alternatives Are Out There?

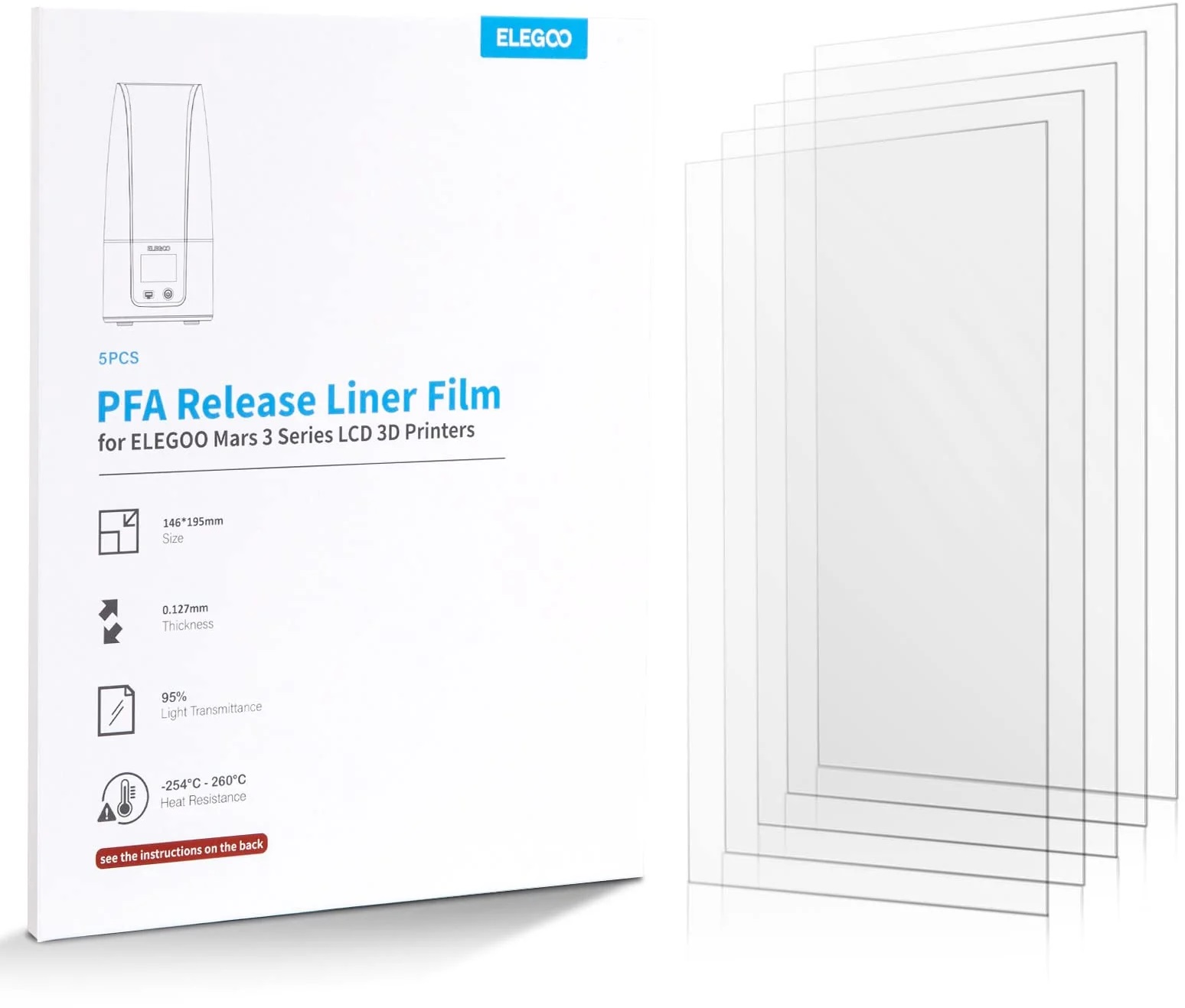

nFEP/PFA: What my initial research led me to believe was two separate materials are, actually, the same picture. nFEP was the term first coined as "Non-FEP" as little was known about its composition when it first came out. Since its early days it has now been given its real name "Perfluoroalkoxy" Yes, I can see why release films are given three-letter acronyms, or TLA's for short!

PFA has a lot to boast in the performance department too, not just a weird chemical name. It has a greater tensile strength, allowing the user to pretend to be a drummer after fitting a fresh sheet into their resin tank. Because we all do that, right? It also has better non-stick properties and a higher air permeability than standard FEP.

That's a lot of words to say that the material won't cause as much vacuum force when printing awkward parts that have voids in places that could cause the part to suck itself onto the release film and cause a printing failure.

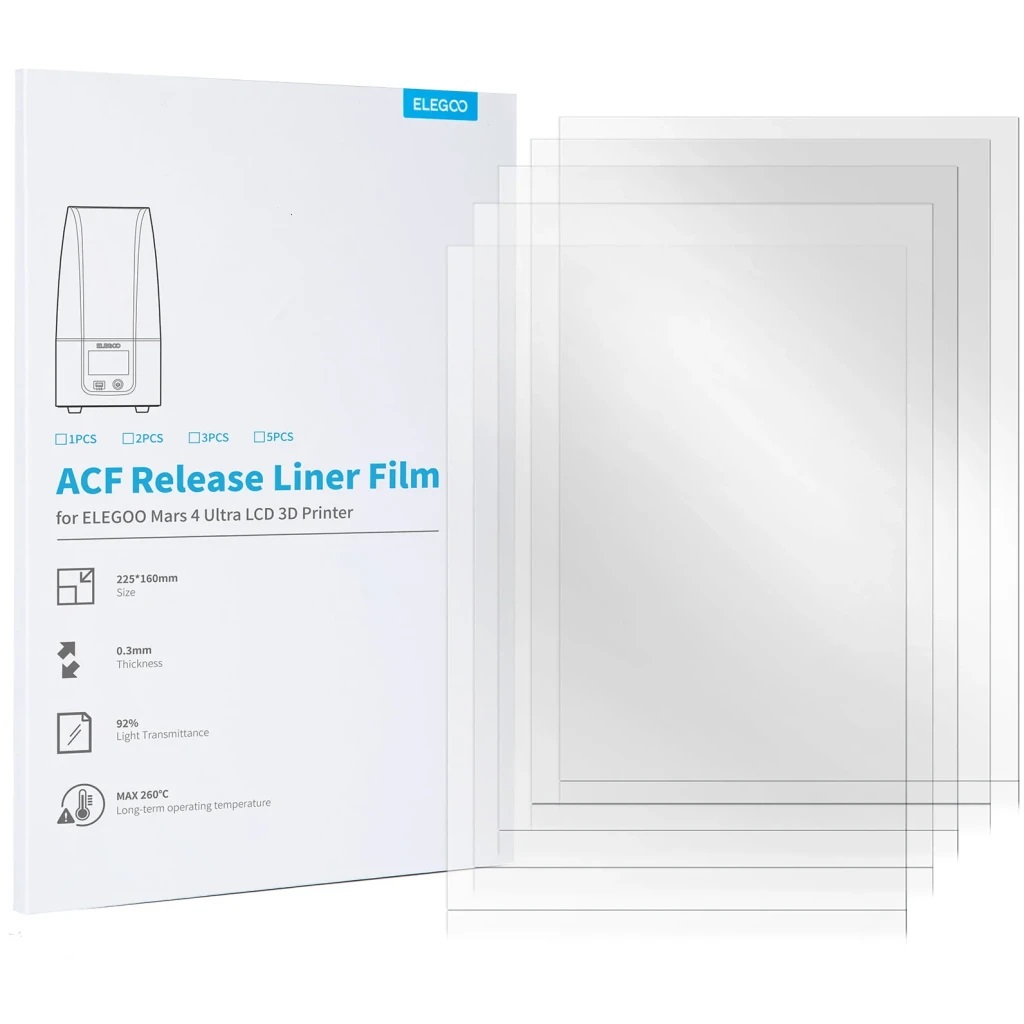

ACF: If you're British then you'll ask me "John, master of tanks, why are you using the Army Cadet Force for your 3D printing?" And to that I say, cheap labour! No, ACF is our third, and final, readily available release film.

So, what is ACF? Good question! The answer is as vague as it is silly. We don't know, because ACF is not a chemical or material acronym and appears to stand for "Advanced Composite Film'' which is wonderful when you've been told to look into release film technology for an article and you smack into a brick wall made of marketing.

What can we discern based on what we already know? Well, the material needs to have non-stick, high wear and good light transmission properties. With that, we can guess it is, again, another grandchild of Teflon which does seem to be the best, if maybe only, material that's most suitable for 3D printing applications.

The problem with ACF seems to come to light, pun intended when reviews and discussions of the material come out. On the r/resinprinting subreddit, many people complain about ACF's lack of light transmission, stating that, it's more opaque than its FEP and PFA alternatives with a higher loss of light through the material and requires longer exposure times to effectively solidify the resin.

Reviews of ACF seem to be, overall, rather mixed. And yes, that should make you concerned. Ameralabs has a brilliant comparison article with fancy graphs and pictures showing ACF compared to FEP of different thicknesses and nFEP. I highly recommend their article for more in-depth reading on the subject. At the time of writing this article, I have not yet used ACF as a release film, but I will be reviewing a machine that comes with it in its resin tank. So take my current opinions as “subject to change”

Conclusion

This article was going to include a "what's the best option" in its conclusion, and after looking over what information is available from the sources I found it wouldn't be right to compare and recommend one product over the other.

I think it would be more honest to state that, in a world where marketing speaks louder than tested and measured fact, it's best to look at what is most widely used by people you trust. There is a trend in many hobbies that I have been involved in for companies to want to sell you the "full package" as an experience. I see it in Warhammer, radio-controlled cars and 3D printing.

Every company, to a degree, wants you to buy their machines, with their peripherals and their consumables, and will sometimes go out of their way to make those items proprietary to their merchandise.

This is dangerous and misleading to the consumer who just "wants something that works" and can often, and easily, be sold a whole package, under one brand name that doesn't fit their needs.

In conclusion, across every article, website, forum thread and Reddit post I used for research for this article, I would state, and stand by, saying that if the release film is FEP or PFA then you have something that has years of tried, tested and proven results. Do not get swept up into the "cult of the new". Allow new materials and new technology to get into the hands of those you trust to give you an honest, well-thought-out review and opinion.

Thank you for reading. I hope this little article looking at Teflon and its non-sticky family has given you an insight into some of the surface-level science and properties of the material we all simply call FEP. With that done it's time for me to return to the garage where I do all the manly things like measure and cut wood, use tools that shoot sparks and get into online debates over the reliability of the Sherman Tank with people who have such wonderful takes such as "Tiger was the best tank because I say so"...

...when we all know, it's the Bob Semple!

Sources

- All 3DP

- Science Direct

- Polyflon

- Ameralabs

- FEPShop

- Aorita On YouTube

- J3D Tech On YouTube

- Reddit - r/resinprinting

Share your thoughts in the comments below and let us know if you have some other 3D Printing basics you'd like us to cover!

"I feel uniquely qualified to, today, bring you an article on the history and development of FEP. No, this is not a joke..."

Supported by (Turn Off)

Supported by (Turn Off)

"What's commonly known as "FEP" in the 3D printing world is the clear film you find in the bottom of your resin tank..."

Supported by (Turn Off)

![How To Paint Moonstone’s Nanny | Goblin King Games [7 Days Early Access]](https://images.beastsofwar.com/2024/12/3CU-Gobin-King-Games-Moonstone-Shades-Nanny-coverimage-225-127.jpg)

Great article* John, and a great run down and insight into the different types I’d never actually considered.

* I hope too many Biscuits Brown where not consumed

Very nice article @johnlyons It made for an informative read. I’m still on the fence about which Resin Printer to buy. So learning more is a welcome addition to my information gathering I’ve been doing.

I look forward to learning more! ??

Interesting article! I didn’t know at all of the different types of film used.

Really interesting article.

Something I learned from experience is that skin tension is important – too tight can be as problematic as not tight enough! There needs to be enough “give” when lifting off so as not to resist too much, and pull your minis off the plate – but not so much as each layer can’t be lifted clear from the FEP.

One reason I love the Anycubic printers – changing FEP is a doddle, and can be done easily (getting the perfect tension) using a Coke bottle top.

Biscuit Brown @johnlyons, Biscuit Brown! It’s biscuit dead fly or nothing. The rest of the article was really informative but sort your ration biscuit selection out ????

I started 3d printing last year with no clue about what I was doing. I’ve learned to keep printing until im out of resin before cleaning the bath. I’m always scared of scratching something or otherwise destroying the machine. I just turn it on and cross my fingers

Great article. I’ve been printing about 5 years and hadn’t even realised there were different film material options. A few film related tips from my own experience: It’s worth noting that as soon as you see a scratch, nick, or any other wear on your FEP (or equivalent) you should swap for new immediately. The cost and time taken to swap the FEP is minimal compared to a punctured FEP letting resin on the LCD and forcing you to replace that. Even if it doesn’t puncture, a rough area on the FEP will cause prints to be more likely to… Read more »

Thanks John I’m looking to get into resin printing and this helped alot, we all know the Churchill was the best? and loving the Gunpla ?