3D Printing For Wargaming Part Two: Why Do We Fail…?

March 30, 2015 by crew

You can read Part One of this series on 3D printing were we talked about the first things you should consider when buying a 3D printer..

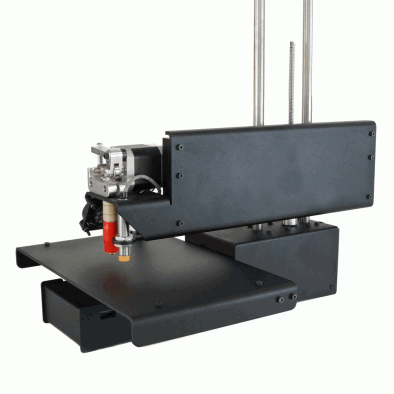

When you first get your machine working you quickly learn the problems with 3D printing. The annoyance of having a print fail after six hours of printing cannot be understated. Fortunately we are part of a hobby where we have some patience and we’re willing to experiment to get good results...

Trouble Shooting

Here’s a basic list of the things I’ve found...

Time - The time sink is pretty heavy. Building a large solid object can literally take days. Depending on the construction of the model you are trying to print, you may even print for a day only to have the print go awry. It is highly unlikely you will be able to fix a problem print, so it’s better to start again.

My solution for this is to design and/or print things in smaller sections, but then you are slowed by needing to be there to remove a finished print and then start a new one. You have to have a particular lifestyle whereby you can take fifteen minutes every two or three hours to tend to your printer.

Materials - This was actually quite surprising. I have had my printer for nearly two months, running regularly and producing quite a large amount of models. I still have not completely used the two kilograms of plastic spool that I initially ordered with my machine. The cost of each one-kilogram spool was US$30 or (checking eBay) about £20. That is pretty cost-effective! It has been mentioned often that not all spools of plastic are created equally and reputable sources are pretty important to the quality of your prints and even the maintenance of your machine.

Noise - The buzzing sound that comes from the machine can be quite distracting, especially when you have it going for hours and hours. Luckily I have a room for hobbies so that, when the door is closed, the sound is not so bad and you can even sleep while it runs. If we were to be living in a small apartment, however, I think we may have been tearing our hair out in frustration.

Quality - There are many things that 3D printing is bad at. Just like any other medium, the trick to creating things that can be considered “of quality” is not only to avoid these limitations but, in some cases, to embrace them.

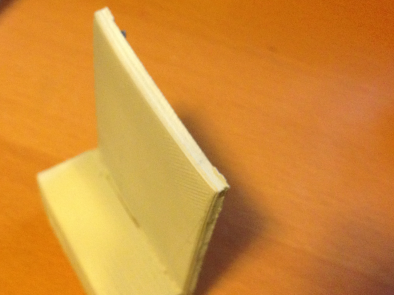

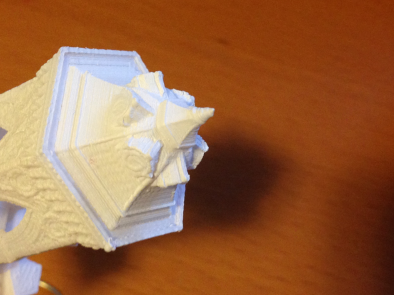

1) Warping - FDM printing is all about temperature control and hot objects that invariably make contact with cold ones. This causes warping. A lot of FDM printers have heated build platforms or even enclosed build areas to help keep the plastic at a higher temperature so that warping is reduced. The example below shows a wall that was printed flat but that warped to a curve. You can see the filler I had to add where it attaches to the block at the base just so the two pieces looked connected.

2) Detached Prints - Similarly, and due to the same reason of temperature, a print can become unstuck from its base because the pressure of trying to change shape as the print cools is greater than the force keeping it stuck to the plate. Heated build platforms and enclosed machines help this.

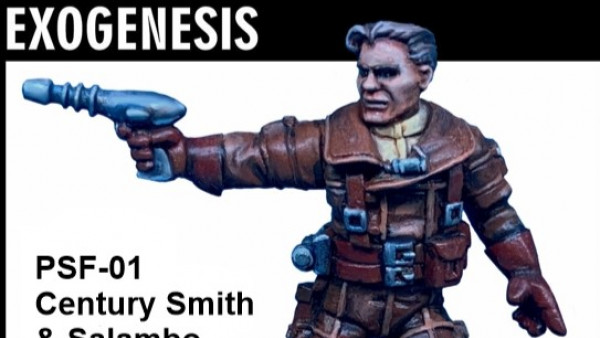

3) Vertical Detail - The plotting action on the printer is very accurate. Even so, drawing, for example, a circle lying flat will always turn out more accurate than drawing a circle vertically that has been sliced into sections. The end result is that not only does vertical detail get somewhat lost, but it also shows a lot of striation that has the feel of a fine rasp if you run your finger over it.

4) Overhangs - You cannot print plastic over empty space. If, say, you decided to print a bicycle standing up, there are just simply parts that wouldn’t print because when you extrude plastic over nothing, you just get strings of plastic everywhere. Slicers are clever enough to add support structure if you ask them to, which helps greatly, but the resulting models are hard to clean up even with a sharp craft knife. One saving grace, though, is that printing models that have graded overhangs (like arches) actually work quite well.

5) First Slice - Stick around for the first five minutes while the printer lays down the first slice. Quite often there is a build up of plastic on the hot end that will eventually fall off somewhere you don’t want it to. Pick it off with some tweezers before it becomes a problem. Additionally, you can notice problems with the slices before the print gets too far along. Don’t touch the hot end though!

6) Tall & Thin - This is a problem with leverage. When the nozzle starts moving around the top of a tall object, it is possible that it will push against some part of the model with even a small amount of pressure that will cause the model to come unstuck from the build plate and the print is ruined.

7) Small Cross Sections - You may see this happen at the end of a print where there is a small tip to your print. The problem is that the plastic doesn’t have time to cool between slices, so the hot end pushes around the previous layer. It gets a little smudgy. It’s important to know this, though, for any detailed print, especially a figurine.

8 ) Finish - The finish on a printed model is not perfect. You can see the lines that have been traced. There are many solutions to this which I shall explore in a later article.

Is Now The Right Time?

Alright. You’ve heard all the failings and problems you might encounter. You think the results speak for themselves and you’re seriously considering it. Here are some more thoughts to help you decide.

This is a hobby in-and-of-itself. Perhaps you’ve spent lots of time working on terrain in the past and you’re willing to replace that allotment of your time in a new field that can create you (arguably) better results. Or if you’re looking to spend more of your free time on something new, then you’ve got a good reason.

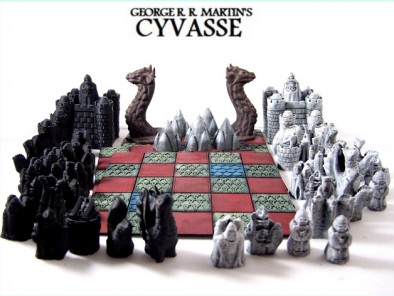

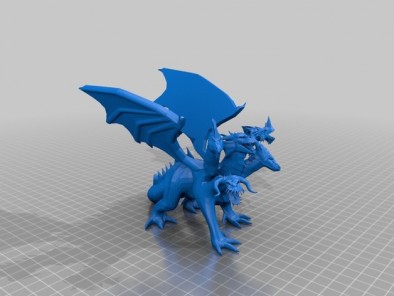

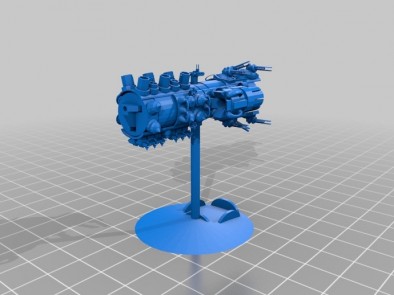

If you don’t want to model your own objects but you want the output prints, then I suggest that you go to model library sites like Thingiverse and search around for potential things you would want to print. They allow you to make a list of things you’re interested in printing. If your list looks large enough and of the quality that you’re looking for then maybe think about it. But if you can’t find things that interest you then come back in six months and look again as these libraries continue to grow.

As it has been said by many, this is a fledgling part of the hobby and industry; it is changing in leaps and bounds. It will go through many revisions and upgrades as it becomes more mainstream. It may be a good idea to wait and see if your favourite company has anything to say on the matter, either anecdotal or with a product for you to consider.

If you are even remotely interested in modelling your own terrain then I suggest giving that a try before buying a printer. Good modeling software can be free (like SketchUp), so you aren’t losing anything by having a go.

Would You Like To Know More?

A video showing the differences between different types of print and highlighting the quality of 3D printing HERE.

In fact, this channel is a very good resource HERE.

Next Time - The next article will show you exactly what you do to make something and print it.

If you would like to write articles for Beasts of War then please contact us at [email protected] for more information!

"...if we were to be living in a small apartment, however, I think we may have been tearing our hair out in frustration"

Supported by (Turn Off)

Supported by (Turn Off)

"As it has been said by many, this is a fledgling part of the hobby and industry; it is changing in leaps and bounds..."

Supported by (Turn Off)

As a follow up, here’s how printing a figurine looks like on my FDM PrintrBot machine. Even something that is 10cm tall looks blotchy and problematic.

http://i.imgur.com/khk7yW4.jpg

Nice series been enjoying it far.

Really enjoying this and while I’m excited for the future these articles are highlighting the limitations of the tech at the moment.

Love the series. good to c a comprehensive guide to 3d printing with pro´s and cons

I’m enjoying the articles. It does give me hope for the future of 3d printing. In 5-10 years we might have printers that can produce quality product at a cost point that is not prohibitive.

Good article. I’m a 3d printer myself and the time spend is big but well rewarded!

It’s still early days I wouldn’t think it is something that will be mainstream until the prices drop and the tech vastly improves. I can see the day when companies are selling schematics for miniatures rather than the physical miniatures. It’s an exciting age indeed I’m still waiting for my self drying clothes and hover board as seen in Back to the Future 2.

Great article series. On the small cross sections issue, is it possible to program in a pause after each slice to allow the plastic to cool more? Have you tried printing two side by side to keep the machine busy and also allow the slice to cool better?

The slicer does actually account for this, good call. They slow the movement of the head down so that the plastic has a chance to cool before the head goes back across it. But I still get issues.

Oh, and yes, I did think about printing a box next to the main model, so that the head moves across to it allowing the previous layer to cool. But doing that does add to the length of the entire print.

im not a fan of it!

i know it sounds harsh but if we can print our own mini’s think of the impact on the community and small companies.

they will surely have to shut up shop!

why would the community buy when we can make our own :(.

It’s a fair point. I have lots of reasons I have been making terrain, but one of them is that I want to compliment the figurines I already have. I find it sad when I take home some really beautiful mini and I put them on a table only to lose all sense of immersion. And, truthfully, I could buy the terrain pieces I’m building, but I found that building them myself was more rewarding. I also knew I would never be able to buy all the terrain that I wanted to in order to have a realistic table of… Read more »

on the contrary i think it could be a boon to smaller companies. in the end they’ll be selling their designs and their software. vastly smaller outgoings, automated sale and delivery, maximising profit. look at the people selling their designs in second life, some have literally made millions!. it will go the same way as music – companies that embrace the new format like apple did with iTunes will end up making profits, companies that don’t move with the times will go the way of HMV.

I think there is a difference in skill sets when it comes to ‘pushing putty’ on dollies to learning brand new computer art package skills and the wastage involved in this that small companies cant afford to endure

Nice article herrigold. Everything has it’s place I think. I work at a Museum, regularly doing model making and moulding and casting of a range of different things e.g. fossils, models, gold nuggets you name it.. There will always be a need for traditional moulding and casting as the results are super accurate, but already 3D scanning and printing are assisting palaeontologists and we are making attempts to work with it, not against it. At this stage, the quality of print is not quite there, unless you have a lot of money. That said, it will only improve. It is… Read more »