Edo Strider for Counterblast™

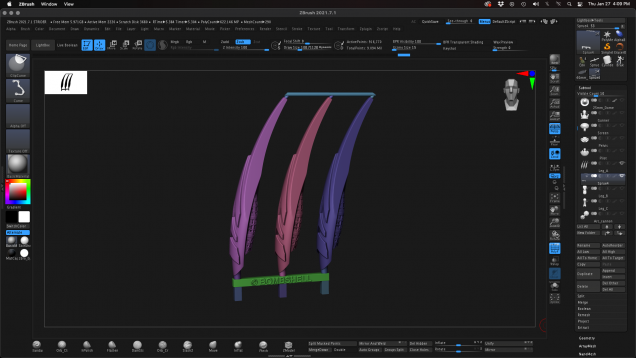

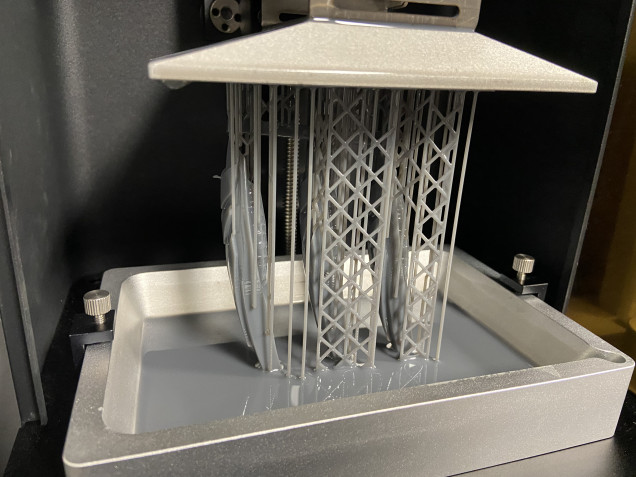

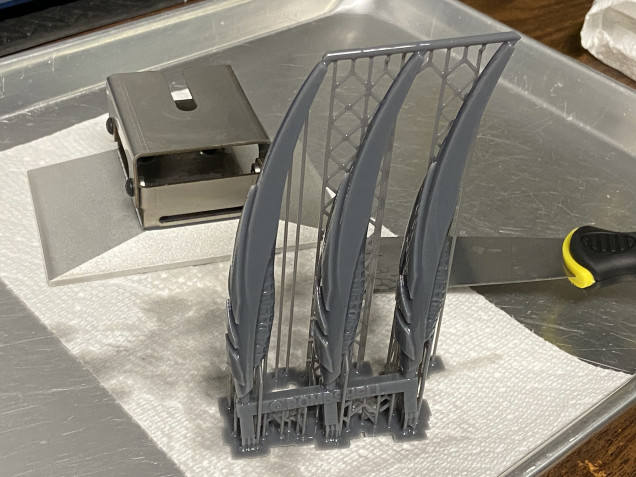

Printing Production Sprues

Since the test prints came out so well the next step in the process is to create parts sprues that will be suitable for making silicone moulds. This requires the same work as it would if the parts were physical and needed to be glued together on a sprue. In this case the parts are attached together with sprues that will serve as the gates and vents of the mould and they will be printed all as one part.

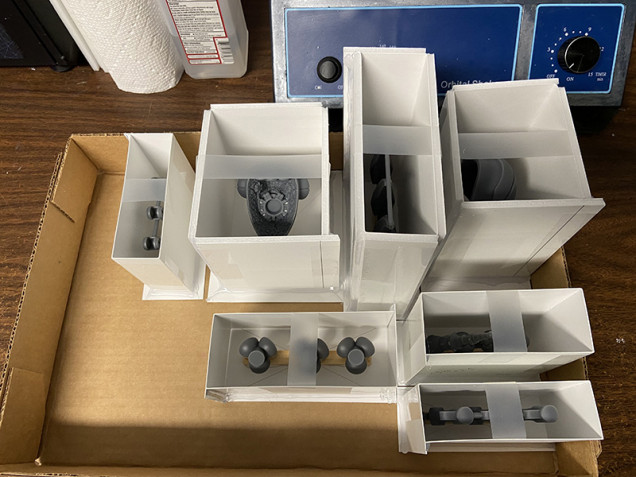

Once the production sprue parts are printed, they are cleaned and sprayed with a matte sealer to protect the resin prints from reacting with the silicone. Some printer resins contain chemicals that prevent silicone from curing properly.

After all the parts have been cleaned and sprayed they are boxed up and ready for the moulds to be poured. Depending on the demand, many duplicate moulds will be made for the production sprues to facilitate casting a number of parts at a time.

Next up will be pouring the silicone, cutting the moulds and running some test castings.

![How To Paint Moonstone’s Nanny | Goblin King Games [7 Days Early Access]](https://images.beastsofwar.com/2024/12/3CU-Gobin-King-Games-Moonstone-Shades-Nanny-coverimage-225-127.jpg)

Leave a Reply