Ad Victoriam

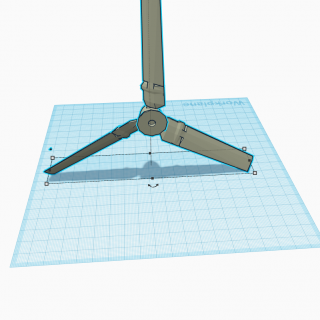

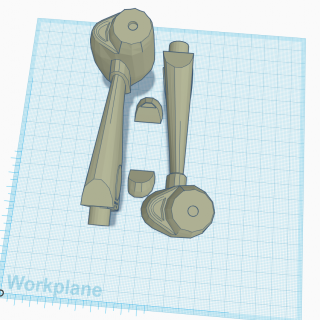

Engine and wings

(01) First successful print at the new scale, but i feel there some improvement needed to make my vertibird easier to assemble.

(02) i started by removing 5.5 mm by 2.5 mm column to insert a 5 mm by 2 mm round magnet in the propellers. It is easier to make the hole larger than the magnet size to compensate for tolerance in printing. If the magnet is too loose i will use greenstuff to fix it in place.

(03) I also added a corresponding hole in the engine of the wings. Also i added a 1 cm peg to end of the wing to make it easier to fix to the body.

(04) Printed the props first at a layer height of .12mm that 3 time my nozzle diameter 0f .04 mm. My print speed was 60mm/s (note the access stringing because of this). The Propellers are about 5.5 inches(15 cm) tall about .5 inch (14 mm) wide.

(05) Printed the wings and engine next. ( note more stringing between the parts)In the future, I may just print one wing at a time to make clean up easier

(06) Behind the scenes not every print was successful. Ran into the normal issue like clogs (left), failed supports(middle), and some under extrusion due to partial clog(right).

That all for now next main body.

Leave a Reply